Mounting head

Mounting heads for hydraulic cylinders are used to attach the piston rod to the machine.

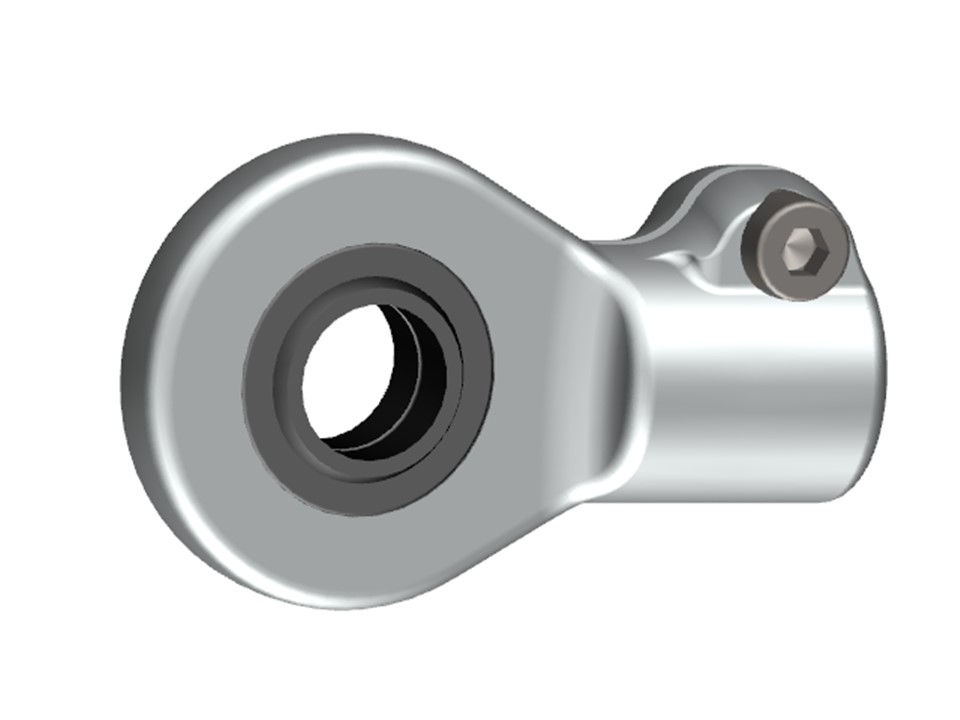

Mounting head with internal thread

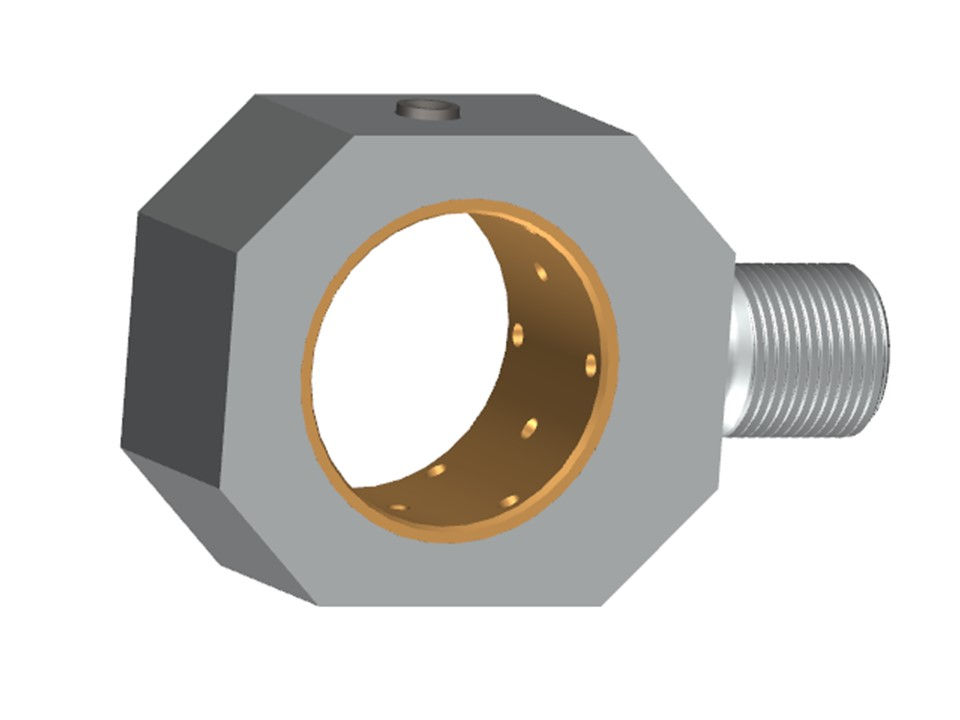

Mounting head with external thread

Mounting the fixing head

- Before mounting, apply screw locking adhesive, e.g. Loctite 243, to the threaded surface. Please note the type of wetting.

- Screw in the mounting head as deep as possible and tighten.

Liquid thread locking compounds fill the thread gap and harden after tightening. This secures the thread.

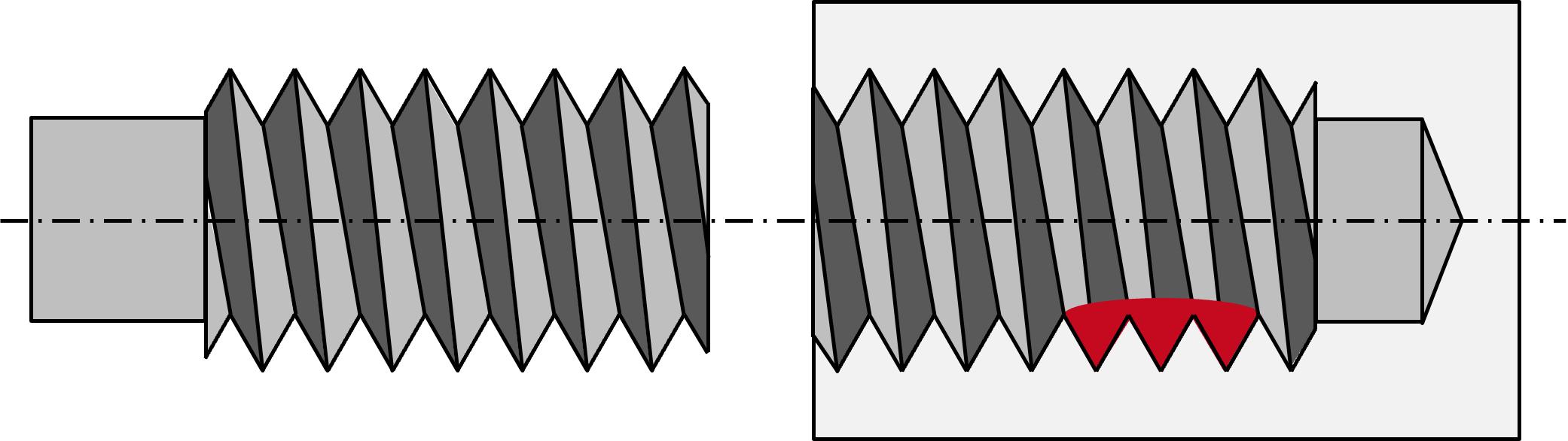

Type A

For internal threads in dead holes (e.g. internal piston rod threads or non-slotted rod eyes), if the enclosed air cannot escape:

-

Apply locking adhesive to the lower third of the internal thread.

Due to the enclosed air, the adhesive is pressed outwards when screwing in and is distributed over the entire thread surface.

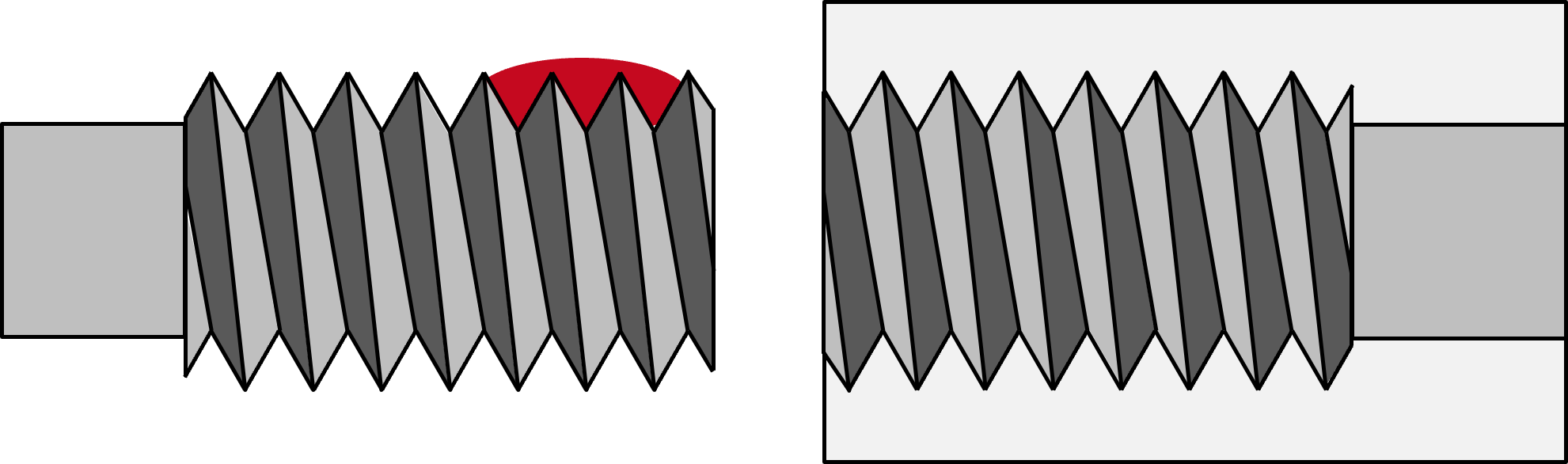

Type B

For open internal threads (e.g. for internal piston rod threads with a through-hole or rod eyes with a slot)

-

Apply locking adhesive to the front third of the screw thread.

When the screw is turned in, the adhesive is pressed inwards and distributed over the entire thread surface.

Tip: Follow our notes on suitable tools

Maintenance of the radial spherical plain bearings

The standard design of the spherical plain bearings requires maintenance. They must be lubricated regularly in accordance with the load and the spherical plain bearing manufacturer's recommendation. Please refer to our instructions in the technical information - spherical plain bearings