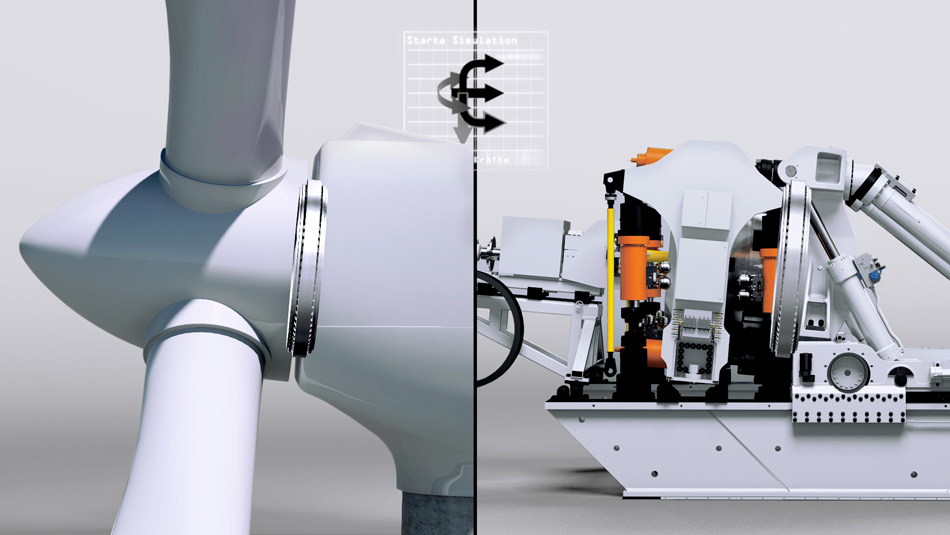

Large-size bearing test stand for wind energy installations

Test hydraulic actuator

Around 40 GW of wind energy capacity is installed worldwide every year. Increasingly larger turbines are being used: 5 MW are common in the offshore sector today, and the 6 MW limit has already been reached. High-performance bearings from Schaeffler Technologies ensure that the bearings operate reliably throughout their entire service life. The key to the impressive quality of these bearings, which currently have an outside diameter of up to 3,200 mm, is the in-house ASTRAIOS testing system.

Servo hydraulic actuator for test systems from Hänchen move this giant that puts the rolling bearings through their paces. It is one of the most modern, largest and most powerful large bearing test stands in the world.

- Hänchen test actuators move one of the world's largest test facilities for bearings.

- Powerful and precise with our hydraulic test actuators.

_neu.jpg?m=1722328695)

The solution supplied by Hänchen

- 8 synchronous test actuators - 4 radial and 4 axial actuators

- Hänchen series 320 with a capacity of up to 1.5 MN

- Stroke of 1 mm and 7 mm

- Integrated inductive position transducers

- Design and delivery of the valve block

Requirement profile

Initially, the large-size bearing test stand ASTRAIOS was supposed to test all bearings of wind energy installations with up to 3 MW. This value was raised to 6 MW later on, because large installations are frequently used by offshore technology. The actual system for a customer was the starting point in this context. Each test cycle of ASTRAIOS adheres to the respective parameters specified by the customers and the coordinate system for strains by Germanische Lloyd and considers the corresponding forces and momentums. The systems have bearings with an outer diameter of 3200 mm. The 16 m long, 6 m wide and 6 m high test stand accommodates single bearings, rotor bearings and pitch-control bearings with an outer diameter of up to 3,500 mm and a weight of up to 15 t. In the past, tests were only possible with bearings of up to 700 mm. The current system allows checking calculations of up to 7,000 mm with high accuracy through extrapolation.

Eight axles are used in the test in the shape of hydraulic cylinders to map the three-dimensional tumbling motion. 300 kW electric and 600 kW hydraulic output allow realisation of the following test parameters: a torque of 150 kNm at a nominal rotation speed of 12.4 min-1 and a maximum rotation speed of 60 min-1. The axial force covers the range of ± 6 MN, the radial force ± 4 MN. The test forces result from the wind pressure for an output of 6 MW, from shear forces through strongly varying wind speeds on the ground and in the sky as well as from the pitching moment caused by gusts. They impact the projected surface of the rotor as well as via the levers of the over 75 m long rotor blades. This is why ASTRAIOS works with a static pitching moment of ± 15 MNm and a dynamic pitching and yaw moment of ± 5 MNm. The indicators force, moment, torque, temperature, flow rate, position, path, shift, oscillation and particles are considered in the process. 300 sensors detect these parameters, 100 of those in a 1 kHz pulse, the others with 10 to 100 Hz. Altogether 8 double-rod servo hydraulic actuators by Herbert Hänchen GmbH & Co. KG perform the linear motions.

Implementation

Test actuators

Four hydraulic radial as well as four axial servo hydraulic actuators are attached on the load frame. They generate the real loads and momentums that occur in a wind energy installation. A pump installation with the power stages 200 kW, 400 kW and 600 kW drives these drives. The basic frequency of the system is 1 Hz; oscillations of up to 10 Hz are possible in case of the superpositioning of forces. Here, the radial servo hydraulic actuators simulate the weight of the rotor hub with the rotor blades of over 100 t. They typically work with a stroke of 7 mm. Each of these radial servo hydraulic actuators of the Hänchen 320 series has a power of 1 MN. With a power of 1.5 MN, the axial servo hydraulic actuators generate the wind loads consisting of the static axial load and the dynamic pitching and yaw moments. The stroke of only 1 mm proves the high performance capacity of the applied Servofloat floating gap seal by Hänchen. Increased abrasion was rectified by optimising the scraper ring. "The cooperation with Hänchen in this and in other tasks was very good and constructive, even after the sale and the installation," emphasises Korn.

Test stand control

The servo hydraulic test actuators that are controlled by force and path are actually completely linear actuators. The integrated inductive position measuring systems are an important element. The very sophistically designed valve block also plays a significant role. Here, the hydraulic specialist from Ostfildern near Stuttgart was responsible for the integration of the entire linear actuator. This sophisticated overall concept allowed commissioning without precommissioning. "Everything functioned immediately," emphasises the head of test facility engineering. The servo hydraulic actuators for test stands that are controlled by force and path are actually completely linear actuators. The integrated inductive position measuring systems are an important element. The very sophistically designed valve block also plays a significant role. Here, the hydraulic specialist from Ostfildern near Stuttgart was responsible for the integration of the entire linear actuator. This sophisticated overall concept allowed commissioning without precommissioning. "Everything functioned immediately", emphasises the head of test facility engineering. "This is excellent engineering art."

Cooperation

The good cooperation between the two companies was the basis for an ultimate test stand which caused a stir all over the world. Schaeffler as client is one of the globally leading providers of roller bearings and linear products and a renowned supplier of the automotive industry for precision components and systems in engines, gearboxes and chassis. With around 79,000 employees worldwide and a turnover of around 11.2 € billion, Schaeffler is one of the largest family-owned industrial companies. The Herbert Hänchen GmbH & Co. KG, founded in 1925, is also a family-owned company that has been supplying its customers around the globe with industrial hydraulic cylinders with 210 employees since 1952. The drive specialists provide series solutions for many application fields without having to revert to expensive special designs with a high prototype risk.

© Hänchen 2014