Hydraulic fluid separator

Pressure converter for all fluids

For a change of fluids without its own hydraulic supply – the pressure remains the same on both sides. A complete separation of the two fluids is possible.

For all pressure ranges and almost all fluids, e.g. for pressure cases in testing facilities for different fluids, or for separating two fluids, e.g. hydraulic oil to water, emulsions, brake fluid or Skydrol®.

- cost-efficient solution

- for all hydraulic fluids

- long service life

- for liquids such as water, emulsions, DOT 4

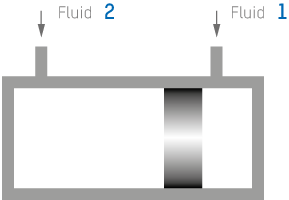

Fluid separator type 1

Liquids may mix

With fluid separators of type 1, leakages of the two fluids can come into contact. This can happen when moving the piston due to the fluid film adhering to the tube wall. For example, mineral oil HLP 68 on one side and mineral oil HLP 32 on the other.

- For fluids that may mix in small quantities

- Extend via fluid 1

- Return stroke via fluid 2

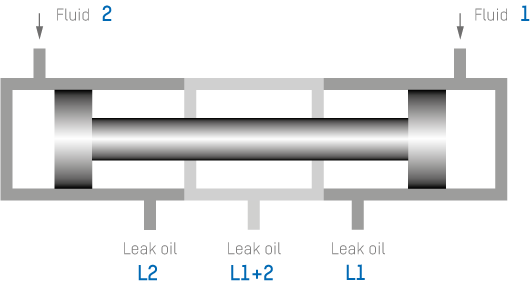

Fluid separator type 2

Liquids must not mix

Fluid separators of type 2 prevent the fluid film of fluid 1 from coming into contact with the fluid film on the side of fluid 2 in the chambers via the moving rod or the tube wall. This is particularly important when using incompatible fluids, such as mineral oil on one side and Skydrol® or DOT4 on the other.

- Spatially separated chambers for fluids that must not mix

- Extend via fluid 1

- Return stroke via fluid 2

- Leaking oil is discharged separately from each chamber L1 and L2 and also from the mixing area L1+2

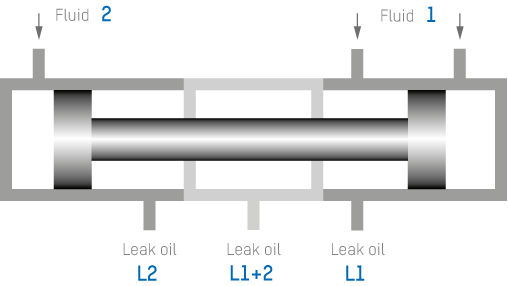

Fluid separator type 3

Liquids must not mix and active return stroke

Fluid separators of type 3 prevent the fluid film of fluid 1 from coming into contact with the fluid film on the side of fluid 2 in the chambers via the moving rod or the tube wall. The two connections in the primary cylinder allow this type 3 to be moved actively. For example, if the fluid is no longer available after the stroke, such as in burst tests or with pulsations in regular operation.

- Spatially separated chambers for fluids that must not mix

- Extend via fluid 1

- Active return stroke via fluid 1

- Leakage oil is discharged separately for each chamber L1 and L2 and also from the mixing area L1+2

Technical data hydraulic fluid separator

Design proposals

| Nominal pressure p1 [bar] |

Effective Ø [mm] |

|

150 |

40 50 80 125 |

|

300 |

50 60 100 140 |

All sizes and pressures on request.

For dynamic use, the stroke of the fluid separator and the amplitude range of the movement and pressure must be taken into account. Information about the two fluids used is required for the design.