Fixation of axes during the production process in a sanding machine

Industrial hydraulic cylinder, clamping unit

Nowadays, fixed concrete rail sleepers are laid on high-speed tracks. "In the precast track elements we have developed for the ICE, we work with a precision of 0.1 to 0.2 mm," says Dipl.-Ing. Stefan Bögl, Head of Research and Development at Max Bögl GmbH & Co. KG.

These large and massive elements are produced under controlled conditions in an enclosed factory building and achieve a much higher quality at the same price than the tracks cast outside directly in the track bed.

A precondition for the precise grinding of the finished elements is their fixation during machining. Despite the mass and size of the blanks, Hänchen industrial hydraulic cylinders and clamping units ensure that they are fixed during machining with an accuracy of 0.01 mm.

- Energy-saving use of the hydraulic drive

- Cylinders position the component to 0.01 mm

- Dirt protection by bellows

- One system: hydraulic cylinder and clamping unit

- Weight of the roadway elements: 9 tons

- Ensure precision accuracy of 0.1 - 0.2 mm

- Protection of the drives against the grinding dust

- Be able to switch off the hydraulics during the sanding process, while at the same time positioning the workpiece precisely

- Industrial hydraulic cylinder series 120 for up to 150 bar

- Bore 60 mm, rod Ø 40 mm, stroke 60 mm

- Force transducer

- Proportional valve

- Guiding system: Servoslide® for speeds up to 0.5 m/s

- Clamping unit Ratio-Clamp® with a holding force of 50 kN

- 0.01 mm exact fixation during machining

Requirement profile

of the application

The classical track bed of ballast has become obsolete for the ICE tracks designed for speeds of up to 300 km/h. The high ballast wear with its consequences for the track geometry and ride comfort causes too much maintenance work and costs and provokes disruptions to operations. This is why railways nowadays lay fixed roadbeds of concrete for heavily used routes. However, up to now the concrete has been cast in situ for the “Fixed Rheda Roadbed” that has been in use since 1972 and was exposed to weathering and other environmental influences during setting. A track panel is hereby laid on a base layer and set in concrete. The “Fixed Bögl Roadbed” that has been approved by the Federal Railway Authority since 2001, on the other hand, is produced in an ultramodern manufacturing plant as a series of fixed elements that are not exposed to weathering.

The manufacturing process

In the first step the blank is cast upside down from special concrete. Two reinforcing mats give it the necessary strength, one is designed as a flat mat, the other has a three-dimensional profile. Six steel billets protrude from each side of the concrete slab and can be bolted to the next roadbed element before the gap is filled with concrete on site. After the mould has been cast in the works, vibrators compact the building material to guarantee that the material ifs free from inclusions. The removed track superstructure sets with a flat underside, whereby the typical material shrinkage takes place under exactly controlled conditions, unlike an outdoor installation.

The track profile

The accuracy needed for the installation of the track supports cannot be achieved purely by precision casting. What's more, the separate elements have to have individual forms since each one is tailor made for the corresponding track and terrain contour. This applies to the curve radii, the junction curves, troughs, summits as well as other terrain contours. Thus, each of the 6.5 metre long and 2.55 metre wide slabs can be given its very own three-dimensional profile depending on the course of the track.

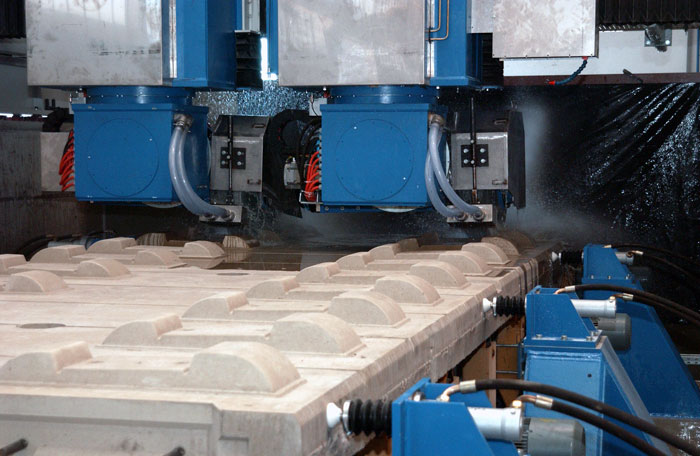

Precision milling in concrete

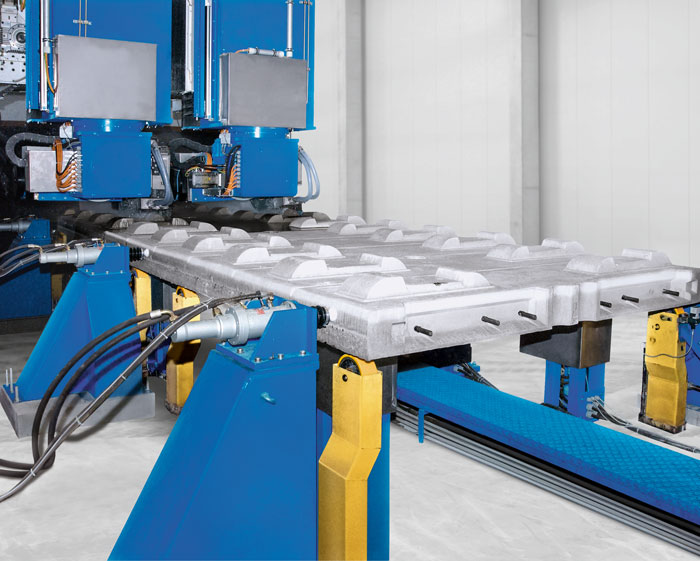

A grinding wheel with a width of 200 mm is powered by a 100-kW spindle and grinds the roadbed elements that have been produced with a 2 mm overmeasure into shape after setting. 2 metres can be processed every minute and up to 2 mm removed by wet grinding in one working cycle. This prevents overheating and the development of excessive amounts of dust. The spindle exerts a cutting force of up to one ton. In conjunction with the size and weight of the roadbed elements of 9 tons, there is thus a risk that the cast parts to be processed may sag in the 0.1 mm range despite the reinforcement. Although the positioning and holding in position of a workpiece is a relatively simple process, the prevalent basic conditions place extremely high demands on the linear drives.

Drive solution

Hydraulic positioning and locking

After the concrete slab has been fed into the machine by a roller conveyor it is positioned by six industrial hydraulic cylinders, each of which is equipped with load cells. There are three cylinders on each side. These three cylinders - two on the left at the ends and one on the right in the middle - are fitted with proportional valves and as linear drives they form part of a control loop that is NC-controlled by a Siemens 840 D PLC. The other three cylinders assume their end-of-travel position while the three control cylinders position the roadbed elements with an accuracy of 0.01 mm. All of the six cylinders have a piston diameter of 60 mm, a rod diameter of 40 mm, a stroke of 60 mm and are fitted with proximity switches. As soon as the final position is reached, four further cylinders are brought into position as a backup. Six servo hydraulic actuators then fix the large workpiece from the sides. These are also designed to absorb any lateral forces that may be exerted on the piston. All servo hydraulic actuators are from the 120 series, suitable for pressures of up to 150 bar and tested to 1.5-times this pressure. The six stroke-holding cylinders and three of the lateral clamping cylinders are designed in a Servoslide® quality. This Hänchen quality is equipped with a special synthetic guide guide for optimum friction characteristics. The sliding surfaces of these guides absorb vibrations, prevent edge pressures and guarantee a largely stick-slip-free movement. The high finishing accuracy and small guide play guarantee a long service life at piston speeds of up to 0.5 m/s. In addition, the grinding heads are clamped by four cylinders.

Hänchen catalogue cylinders

Bögl catalogue cylinders from Hänchen. The industrial hydraulic specialist has invested millions over the past few years to convert the overall engineering and development to a versatile, three-dimensional CAD system that is specially designed for a modular construction. This modularisation is so fundamental that each bore contour represents a module that is only stored once in the central system. Our customers can access the spatial representations of these modules from their PC via an online configurator HÄKO. The company from Ostfildern near Stuttgart thus offers versatile, bespoke product variants without the costs and uncertainties of a special design.

Safety rod clamping unit in special design

Ratio-Clamp®

All of the cylinders from below and three of those on the sides are fitted with the patented rod clamping unit Ratio-Clamp® from Hänchen. One of the lateral clamps of the type RCS 40 with a diameter of 40 mm is a special design and has been modified to absorb lateral forces without any damage. All clamping units boast a retention force of 50 kN as soon as there is a pressure loss in the hydraulic system. They thus allow processing with a depressurised fluid circuit. The Ratio-Clamp® clamping unit has also been tested by the TÜV and also assumes safety tasks during manufacturing itself since the clamp is only released when a pressure is present. The rod can be moved in both directions in this switching state. A loss of pressure releases the energy stored in the springs that apply the retention force on the rod via a conical clamping element. This process can be triggered automatically by a specific pressure drop from the control, though also by an energy failure or system damage. The clamping force is retained for an indefinite period with no energy supply until the release pressure is applied and the piston rod can thus be moved freely. The system will not be damaged even if the rod is occasionally moved over a short distance if the set retention force is exceeded. This means that the concrete slab can be held exactly in position during the half hour processing time without any hydraulic pressure or control. The Ratio-Clamp® hydraulic clamping devices comes as a complete unit in the standard design or in conjunction with a industrial hydraulic cylinder. The customer can build or convert this solution in the configurator HÄKO with a scaled CAD-object showing all fitting dimensions or export it as a 2D or 3D data set, for example to an Autocad format.

Large components as precision products

Thanks to hydraulic cylinders and rod clamping units

A successful co-operation

After milling, the concrete slabs receive an identification number to ensure that the right support is laid at the right location. The "Fixed Bögl Roadbed" will initially be laid on a 70 km section, an innovative project that forms part of a versatile portfolio: the Frankian family-owned business, now in its third generation, can offer everything from a ready-built house to a turnkey football stadium for the World Cup. The enterprise has 4,000 employees and makes a turnover of 750 million euros.

New paths with concrete

With the production of the "Fixed Roadbed", Bögl and Hänchen prove that completely new paths are open for the processing of concrete: large components can now be used as precision products too. Both enterprises were able to concentrate their competence in this project: the hydraulic specialist demonstrated the great efficiency and precision of its industrial hydraulic cylinders, even under tough environmental conditions, and the possibilities offered by the modular design and product system to solve even complex tasks without special designs as well as a new approach to a complete hydraulic axis including clamping. “The co-operation during the development period between September 2002 and October 2003 as well as the three-shift production that has been running since then certainly paid off for us”, confirms Stefan Bögl. And the family-owned business exemplarily demonstrates whole new perspectives for construction elements through its own research and development division, elements that can be produced under exact environmental conditions in an as yet unknown precision and repeating accuracy. Despite the crisis in the building trade, the company has as yet been able to secure its jobs and keep in the black with this innovative concept for a complete solution.

© Hänchen 2005