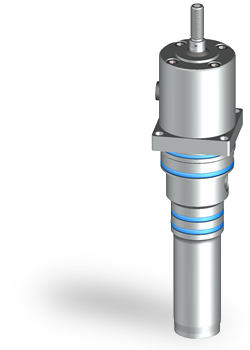

Individual constructions

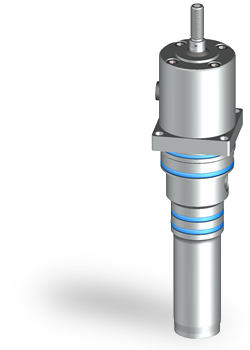

Screw-in cylinders

- Small construction volume

- Easy installation without screwed fittings

With decades of expertise in developing and manufacturing special solutions, our development team is always there for you. Whenever possible, we use minor modifications of our modular standard elements to adapt them to your requirements as cost-effectively as possible. If necessary, we can even develop entirely new solutions for you.

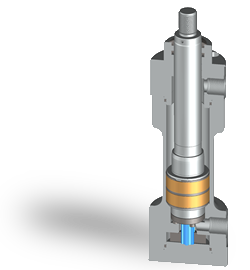

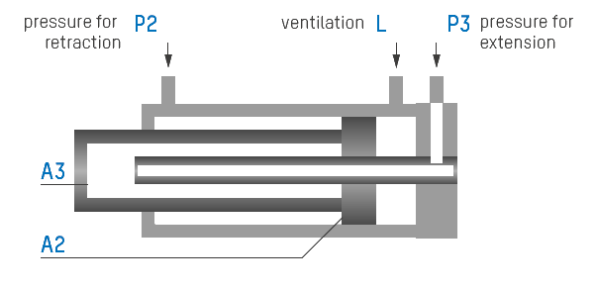

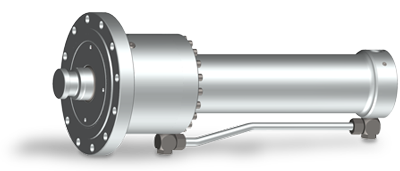

If simple adjustments don't suffice, we'll design complete customized hydraulic cylinders to suit your requirements. Whether you need cylinders with special damping, for dosing, injection, weight compensation or oscillation. Here you can see some examples for such special solutions.

Possible fields of application are:

Read more about Hänchen high quality hydraulic cylinders.

Already our Industrial hydraulic cylinder fulfil highest technical requirements.