Hydraulic pressure intensifier

The pressure booster

Hydraulic pressure intensifiers can also be used as fluid transformers to separate two different fluids.

- cost-efficient solution for cyclic operations

- pressure increase up to 4,000 bar

- suitable for temporary high-pressure requirements

- saves energy in hydraulic systems

Mode of functioning of hydraulic pressure intensifiers

The secondary side can operate with almost any fluid

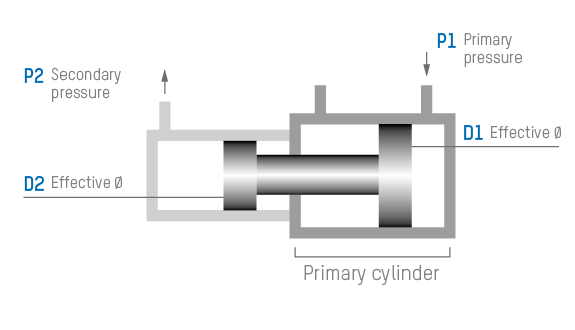

General mode of functioning of pressure intensifiers

In the hydraulic pressure intensifier a surface A1 with the effective diameter D1 is pressurized with the primary pressure p1. The resulting force generates an intensified pressure p2 (secondary pressure) with the effective diameter D2 on the smaller surface A3, which corresponds to the area ratio.

Function and application in test applications

With a hydraulic cylinder actuated by a servo-hydraulic drive (primary cylinder), any operational profile for the piston rod can be created. This operational profile creates a certain pressure pattern in the high-pressure chamber, which can be applied to a test object as test pressure.

Component parts can, for example, be vibrated with internal pressure - ideal for bursting tests of hollow objects such as hoses, pipes and containers. The test actuator can work with hydraulic oil, while the high-pressure part uses water or other environment-friendly fluids.

Technical data of our hydaulic pressure intensifiers

Design proposals

| p2 [bar] |

D1 [mm] |

D2 [mm] |

Transmission ratio |

p1 [bar] |

Dynamics |

|

630 |

100 125 160 |

60 80 100 |

2.78 2.44 2.56 |

227 258 246 |

up to 20 Hz* |

|

1,600 |

125 160 200 |

50 60 80 |

6.25 7.11 6.25 |

256 225 256 |

up to 10 Hz* |

|

4,000 |

125 160 200 |

30 40 50 |

17.36 16.00 16.00 |

230 250 250 |

static |

All sizes and pressures on request.

* The dynamic limits depend, among other things, on the stroke resp. stroke volume of the intensifier and the amplitude range of the secondary pressure p2. These data influence the service life time via the fluid compression and pressure rise times and must be calculated for the application.