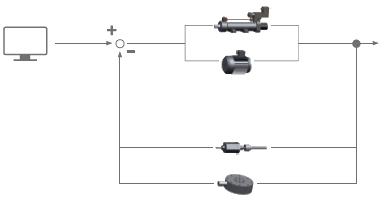

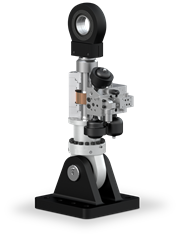

Hydraulic linear drive in punching machines and test stands

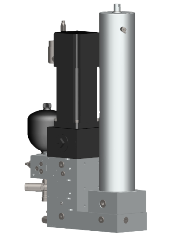

Custom hydraulic cylinder

Here you can find user reports on the application from a manufacturer of industrial hydraulic cylinders, clamping devices, and drive systems in systems and machines. We convince our customers with:

The oscillating movement of the ingot mould, driven by the hydraulic cylinder, ensures an optimum quality and smooth flow of 3 mn tons of high-tech steel every year. The 25t ingot mould hereby oscillates at up to 3 Hz with a random vibration profile.

The company is charged by some of its customers with the task of checking the quality of its safety-relevant components on its own and then delivering them straight to the assembly line. One of these components, which must fulfil the most stringent of requirements, is the industrial hydraulic cylinder for the pressure die-casting systems.

We have a wide range of hydraulic cylinders, which you can configure yourself in our HÄKO configurator. We are also pleased to support and advise you in your selection. And if you want something special, we can customise our cylinders to your application.

We have been producing hydraulic cylinders since 1952 and love to master even the most difficult requirements. We therefore have a high level of expertise in the design and manufacturing of high-quality hydraulic cylinders.

Hänchen stands for:

Our products are state-of-the-art, energy-efficient and reliable. We achieve this with our highly competent employees who are specialised in their field.

Haenchen fulfils its role as a consultant with integrity and transparency. We always look for the best solution in the interests of our customers.

Our machinery is carefully selected and constantly expanded to ensure high production quality. This enables us to achieve durable and robust products.

We design our products for a long service life in terms of use and maintenance. You can still get spare parts and support from us even years later.