Components for hydraulic test stand technology

Hydraulic actuators, hydraulic control blocks, test machines

Optimal test machine operation can only be achieved if you have the right hydraulic test stand components.

This starts from machine elements for jig construction, drive elements such as hydraulic cylinders or hydraulic test cylinders for linear movements and extends to safe controlling, which is achieved with the help of electronic controls and hydraulic control blocks.

Hänchen manufactures many components for test stand construction and also provides the implementation of complete, individual test machines.

our passion.

Managing Director and Sales Manager

Herbert Hänchen GmbH

by Hänchen

- Custom-made for your application

- Floating gap seal for friction-optimised use

- Servoseal for less leakage at the piston

- Control blocks for your safety

Machine elements

For test stand construction

Various elements are needed to attach, move or secure machine parts. Hänchen offers a selected range of special machine elements:

- Clutch rods and shafts

Do you need special machine elements made to your requirements for your test stand? Hänchen manufactures unique single pieces and small batches of rods, shafts and axles to your individual specifications.

- Mounting elements

The connection of test specimens to the drive elements and to the test setup must be dimensioned according to requirements. For this purpose, it is important to take into account the dynamic and static stresses (such as forces or accelerations) both in the stress direction and across it.

Hänchen offers the right add-on elements for this purpose. For further information, go to mounting elements.

- Load holding devices

A risk assessment is required according to the EU Machinery Directive. These requirements are preferably implemented constructively or through control measures. All loads, which may come down due to an emergency stop, power failure, temperature differences or leaks, must be secured constructively.

To do this, Hänchen provides the clamping device Ratio-Clamp®. Find out more about this on the product pages of our clamping device.

- Pressure chambers and sealing bushes

Appropriate pressure chambers are required for testing components under fluid pressure. These either enclose the test specimen completely or lead the test specimen (e.g. a shaft) completely outwards. The movement is initiated from the outside.

The seal on the feedthroughs must be designed for hydraulic pressure and the chemical-physical resistance of the fluid must also be taken into account.

Hänchen manufactures sealing systems and guiding elements to your individual requirements. If necessary, we can also engineer these components for you.

Drive elements

For the test setup

Hydraulic or electric? The right drive technology depends on the application and environmental conditions as well as on the requirements of the motion profile. Hydraulic systems offer you the following advantages:

Simple generation of enormous forces

- High power density

- Compact construction

Low inertia resistance

- Start from standstill at full load

- Simple reversal of the direction of movement

High control accuracy

- Fast, sensitive, uniform and stepless speeds

- Simple control concepts with widely varying performance requirements

Long service life despite continuous and simultaneous performance

- Force (~ depends on pressure)

- Speed (~ depends on flow rate)

Hydraulic drives

By Hänchen

- Servo hydraulic actuator

Hydraulic servo cylinders are ideal for static testing tasks and tests up to 25 Hz. These linear drives are also particularly suitable for testing tasks with long strokes. Find out more about this on the product page of servo hydraulic actuator.

- Pressure transformer

Hydraulic pressure transformers convert fluid pressure to a higher or lower value. If the conversion ratio is greater than 1, it is referred to as a pressure intensifier; if it is less than 1, this is referred to as a pressure reducer.

Pressure intensifiers are used to generate very high pressures. Applications include, for instance, test applications for internal pressure burst tests or dynamic pressure tests.

Learn more about our pressure & fluid transformers.

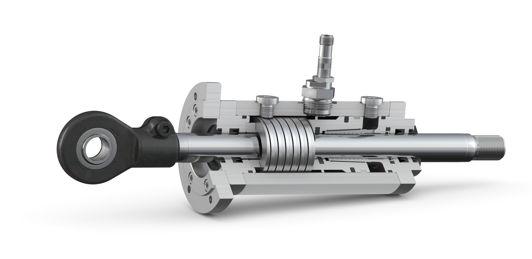

- Test hydraulic actuator

Hydraulic test actuators are ideal for highly dynamic tests with high frequencies and small amplitudes. These linear drives are available as light and heavy designs for high inherent stiffness. Read more about our servo actuators for test systems here.

- Rotary-linear actuator

Mechanical tests often require the combination of a linear stress and a rotational stress. So-called tension-torsion tests require a linear force, which is generated by a hydraulic cylinder. This is superimposed by torque generated by a rotary motor.

The appropriate drive elements must be selected depending on the stress type (static or highly dynamic).

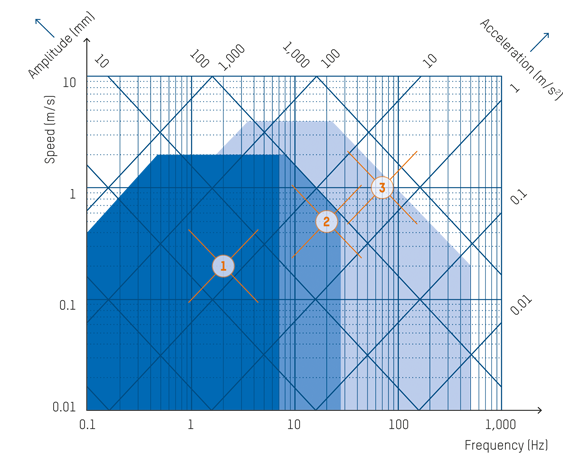

Selection of the right hydraulic test cylinder

Based on the dynamics of the movement profile

The appropriate hydraulic test cylinder for your application is decided on the basis of various technical criteria such as:

- Frequency

- Amplitude

- Speed

- Acceleration

- Control-oriented behaviour

Use our HÄKO product configurator to help you design the right hydraulic cylinder or test cylinder.

![]() Double-rod cylinder series 320

Double-rod cylinder series 320

![]() Double-rod cylinder series 120 and 300

Double-rod cylinder series 120 and 300

![]() Single-rod cylinder series 120 and 300

Single-rod cylinder series 120 and 300

Control

Simply safe

The movement-related technological parameters and the requirements of the EU Machinery Directive require suitable control components. This is achieved with the help of electronic controls in combination with hydraulic control blocks.

Hydraulic control blocks

Control blocks or so-called valve blocks are used in test machines for all sorts of tasks. Various functions can be compacted together in a single block via add-on and built-in valves, with no additional cables.

Hänchen takes on the engineering and implementation of the control blocks. Functions include:

- Switching on, for smooth and jolt-free starting

- Shutting off to separate cylinder chambers or drive axles from the fluid supply

- Setup operation, for proceeding at reduced speed

- Short circuiting of the chambers, for control-oriented damping optimisation or load-free switching

- Fluid distribution, for distributing the flow of fluid to different consumers

- Accumulator connection, for mounting hydraulic accumulators

Customised software for test stands

A hydraulic system can map complex processes through automation with electronic components and software. It also allows the creation of safe controls.

The software is customised to your exact application, combining standard software elements with custom modules.

- Automation of motion sequences

- Implementation of complex control circuit structures

- Creation of safe controls

Systems

Test stand, test machine according to EU regulations

Test stands and test machines must be designed in accordance with the EU Machinery Directive. This applies to all machines placed on the market, including machines intended for own use in development and test centres.

It is therefore always necessary to apply the relevant conformity assessment procedures for complete or partly completed machines.

Hänchen can implement complete, individual test machines and design individual modules or partly completed machines for integration in machinery.