Mounting elements

small batches and unique single pieces.

Since 1925, when we started designing hydraulic cylinders, Hänchen has been manufacturing precise mounting elements. Right from the beginning, we have made it a priority to realize individual solutions – whatever you need for your application.

For forces from 1 kN to 6,000 kN. Following DIN, ISO, or your own standards – we make products on the basis of your engineering drawings and handle the entire engineering part for you, including consultation.

- realizing your requirements

- component parts with large diameters up to 200 mm

- small batches and unique single pieces

- made in Germany

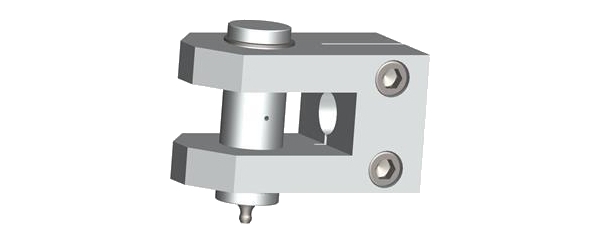

Fixation parts and clevis brackets

For connecting pivoting elements such as gear or articulate rods, plain rod eyes

with bronze bushings, rod balls, or rod clevises are suitable options. With the appropriate clevis brackets, they are easily mounted in the machine. We select the best bearing material for your application: greased bronze bushings, or maintenance-free synthetic bearings.

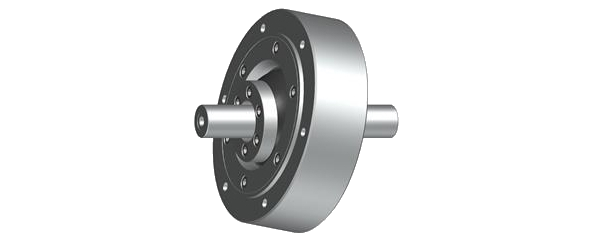

Pivoted mounting elements

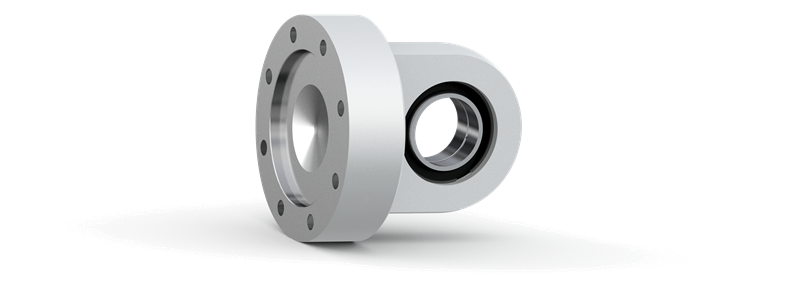

Mounting flanges

Spherical bearing flanges