Mould oscillation in a steel mill

Custom hydraulic cylinder

- Maintenance cycle of 6 years

- Small amplitudes of 3-4 mm

- 200 million load changes without inspection

- Wear-free sealing system

- Oscillation of a 25 t mould

- 3 Hz with any oscillation profile

- Fail-safe hydraulic cylinders

- Long maintenance cycles

- Hydraulic cylinder of the 320 series

- Force of 400 kN

- Servofloat® quality for a wear-free sealing system

- 80 oscillations per minute with a stroke of ± 3-4 mm

- Maintenance cycle is 6 years / 200 million load changes

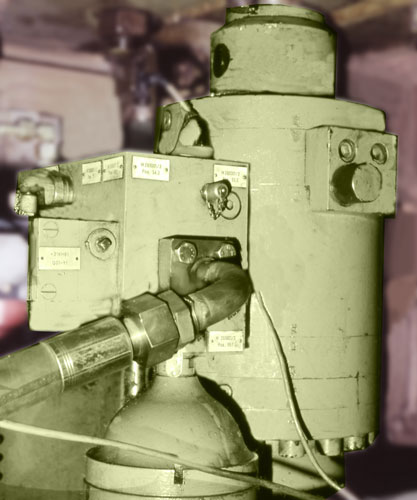

Following several development stages, which were dominated and pushed by SMS Demag, the current state-of-the-art is hydraulically driven resonance oscillation. ThyssenKrupp Steel AG in Duisburg-Bruckhausen uses a hydraulically driven short-lever oscillation system from SMS Demag AG. The molten flow of steel is formed into the rectangular, so-called strand in the ingot mould, which is molten on the inside and has a solid surface. The subsequent strand guide supports the strand. The strand is then fully hardened with spray cooling. This strand guide consists of 13 groups of rollers, the so-called segments, that have a number of tasks: they prevent the steel strand from bulging to size larger than a defined thickness of 215 mm at a width of 1,800 to 2,600 mm. And they align the strand from the vertical to the horizontal – with a radius of 9.3 m. Furthermore, they also allow a water cooling of the strand so that the steel strand is fully hardened when it is cut into slabs at the end of the casting machine.

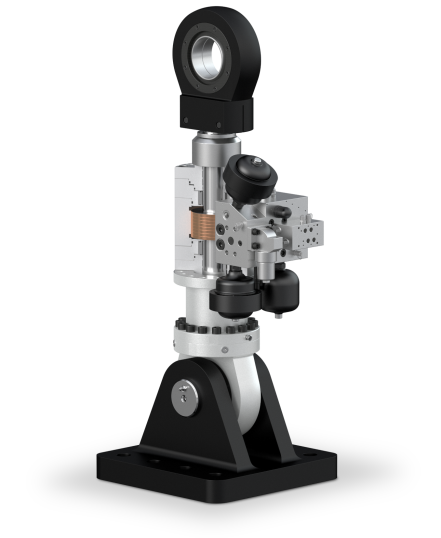

The hydraulic ingot mould oscillation developed by SMS Demag AG ensures that the ingot mould always moves relative to the steel strand thanks to the use of a custom hydraulic cylinder. This oscillates continuously in a vertical direction, whereby the movement simultaneously is used to introduce the fluxing agent between the strand and wall of the ingot mould. Each of the elevating platforms in use are moved by two Hänchen hydraulic cylinders from the 328 series in a Servofloat® quality with the patented floating annular gap seal.

They oscillate during normal production with 80 vibrations per minute and a stroke of ±3-4 mm. The cam profile - like the amplitude and frequency – can be freely modified during operation to keep the relative movement of each single oscillation between the ingot mould and strand exactly constant. Since the strand itself has an inherent movement on account of the casting speed, the downwards movement of the ingot mould must be much faster than the strand's own movement. Hänchen thus designed the cylinder as highly dynamic and practically friction-less. The movement is recorded by a magnetostrictive position transducer system and controlled with an industrial PC, which in turn ensures the connection to the process control computer.

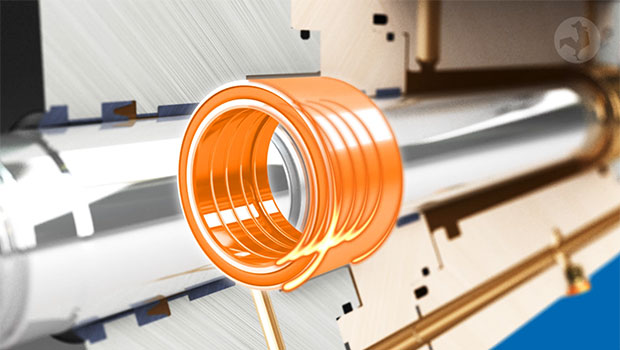

The patented floating annular gap seal in a Servofloat® design is used in the controlled servo hydraulic cylinders, that exert a force of 400 kN. A steel liner hereby follows the radial deflection of the piston rod with a seal gap of only a few 1/100 mm that is kept practically constant over the entire pressure range. However, this method only works with a production accuracy of a few μm since the leakage would otherwise lead to high hydraulic losses.

Cylinders in a Servofloat® quality offer maximum positioning and repeating accuracy thanks to their negligible friction, are stick-slip-free and suitable for very slow and fast movements. Thanks to the practically friction-free design, this type of cylinder does not wear, even after extremely long periods of use. This corresponds to a requirements profile where maximum availability takes top priority. High demands are placed in particular on the purity of the fluid: the filter is replaced as necessary, the two pumps that generate the operating pressure of 260 bar are replaced every 35,000 hours. Particles are counted and the servo valve replaced once a year. 3D measurements on the elevating platform with an accuracy of 10 μm that record and show any change to the oscillating movement are also used for quality control. „We originally planned to service or replace the cylinders each year“, reports the technical coordinator for maintenance at ThyssenKrupp Steel AG, Dipl.-Ing. Marc Ramacher. „But the replacement cycle for a general overhaul was initially increased to two, then four and now six years. Even after this period of time we still do not have to completely replace the Hänchen cylinders. They only have to be sent to Hänchen for a check and general overhaul.

- Tin strip steel for drinks cans, for example, a particular challenge on account of the very thin tin plate.

- Steel for dynamos and transformers.

- Sheet metal - for example for shadow masks in televisions.

- IF steel for the automobile industry.

- Other special steels that differ in their hardness, brittleness and composition.

© Hänchen 2006