Standard hydraulic cylinder according to DIN and ISO

Mounting dimensions according to DIN ISO 6020/6022

Honed surfaces, geometrical accuracy, long service life. Although the mounting dimensions and accessory options are according to applicable standards, these series convince through their inner Hänchen values.

Read more about Hänchen high quality cylinders with harmonized sealing elements, these cylinders fulfil highest technical requirements – for safe and reliable drive control.

- extremely long service life

- mounting dimensions according to DIN and ISO

- equipment according to DIN ISO 8132

- extremely long service intervals

- honed sliding surfaces

- high accuracy of the components

DIN and ISO standards for hydraulic cylinders

There are a number of standards for hydraulic cylinders: The dimensioning standards are intended to guarantee exchangeability between the products of different manufacturers. For round-head cylinders, the following standards apply: DIN ISO 6020-1, DIN ISO 6022. The equipment for standard hydraulic cylinders, such as spherical rod eyes, comes under DIN ISO 8132.

So, the dimensioning standard defines the mounting dimensions of standard hydraulic cylinders, but not the quality or the material of the hydraulic cylinder.

See also: http://www.iso.org

Tip: Always compare the standard dimensions of different manufacturers since the standard allows a lot of leeway.

Hänchen DIN / ISO standard hydraulic cylinder series

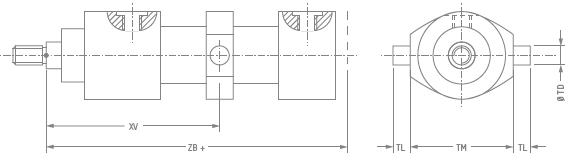

Comparison of standard hydraulic cylinders DIN/ISO with the same mounting dimensions:

left Hydraulic cylinders according tió ISO 6022 with cushioning,

right Hänchen compact hydraulic cylinders of the 550 series without cushioning

Accessories and equipment for standard cylinder DIN/ISO

Mounting elements, assembly tools and tools

In the product configurator HÄKO, you can find our available standard ISO 8132/8133 compliant accessories and other equipment to match your chosen cylinder.

Technical data for standard DIN / ISO hydraulic cylinders

Type of effect: single-rod cylinder | Sealing systems: basic design, Servocop®, Servofloat® | Speeds: up to 0.5 m/s | Stroke: 1 - 6,000 mm

The hydraulic calculation of hydraulic cylinders, as well as the selection of suitable accessories, valves and data sheets can be done by you in our product configurator HÄKO.

| Series 160 DIN ISO 6020-1 |

Series 550 DIN ISO 6022 |

||||

| Bore (mm) |

Rod Ø (mm) |

Force F1 | F2 (kN) |

Max. pressure (bar) |

Force F1 | F2 (kN) |

Max. pressure (bar) |

| 25 | 14 | 7.9 | 5.4 | 160 | --- | --- |

| 32 | 18 | 12.9 | 8.8 | 160 | --- | --- |

| 40 | 22 25 28 30 |

20.1 | 14.0 --- 20,1 | 10.3 --- |

160 --- 160 --- |

--- 31.4 | 19.1 --- 31.4 | 13.7 |

--- 250 --- 250 |

| 50 | 28 30 36 40 |

31.4 | 21,6 --- 31.4 | 15.1 --- |

160 --- 160 --- |

--- 49.1 | 31.4 --- 49.1 | 17.7 |

--- 250 --- 250 |

| 60 | 40 50 |

--- --- |

--- --- |

70.7 | 39.3 70.7 | 21.6 |

250 250 |

| 63 | 36 45 |

49.9 | 33.6 49.9 | 24.4 |

160 160 |

--- --- |

--- --- |

| 80 | 45 50 56 60 |

80.4 | 55.0 --- 80.4 | 41.0 --- |

160 --- 160 --- |

--- 125.7 | 76.6 --- 125.7 | 55.0 |

--- 250 --- 250 |

| 100 | 56 60 70 80 |

125.7 | 86.3 --- 125.7 | 64.1 --- |

160 --- 160 --- |

--- 196.3 | 125.7 --- 196.3 | 70.7 |

--- 250 --- 250 |

| 125 | 70 80 90 100 |

196.3 | 134.8 --- 196.3 | 94.6 --- |

160 --- 160 --- |

--- 306.8 | 181.1 --- 306.8 | 110.4 |

--- 250 --- 250 |

| 140 | 100 | --- | --- | 384.8 | 188.5 | 250 |

| 160 | 90 110 |

321.7 | 219.9 321.7 | 169.7 |

160 160 |

--- --- |

--- --- |

| 200 | 110 140 |

502.7 | 350.6 502.7 | 256.4 |

160 160 |

--- --- |

--- --- |

F1 = Compressive force while the cylinder is extended | F2 = Compressive force while the cylinder is retracted