Hydraulic vibration dampers - Structure-borne sound absorbers

Hydraulic silencer for fluid systems

Unpleasant noises can occur in hydraulic lines for two reasons:

- Alternating volume flows generate pressure shocks and therefore loud bangs. The use of a hydraulic accumulator helps here.

- Hydraulic positive displacement pumps, such as gear or piston pumps, cause a discontinuous, pulsating oil flow which results in undesired vibrations and high noise levels. To prevent this problem, Hänchen offers the hydraulic silencer, also known as vibration dampers and structure-borne sound absorber.

- Smoothes the fluid flow

- Minimizes noise exposure

- Reduces disturbances of the sensor technology

- Easy to integrate in the fluid circuit

Mode of functioning of the hydraulic silencer

How to reduce vibrations in lines

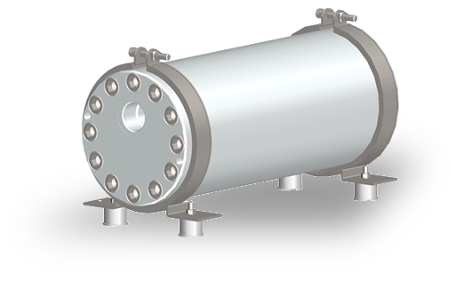

The pulsating oil flow coming from the pump is channelled through the vibration and structure-borne sound absorber, where it is split into a large number of partial flows. Each of these individual flows causes turbulence in the oil flow. This multiple reflection smoothes the total oil flow, which means that the amplitude of the vibration is reduced almost to zero, so that a low-pulsation oil flow emerges from the hydraulic silencer. The conversion of the vibration energy is practically lossless. The flow resistance is less than 1 bar.

Vibration dampers are particularly effective at frequencies between 150 Hz and 2,000 Hz.

The hydraulic vibration absorbers or structure-borne sound dampers from Hänchen are maintenance-free.

Installation prerequisites

Quick installation

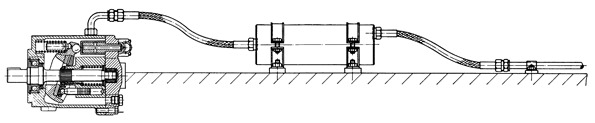

Vibration and structure-borne noise dampers are installed directly in the pressure line, preferably close to the pump. They can be installed in any position, but the outlet port must always be at the highest point so that the hydraulic noise damper vents itself.

The inflow port is connected to the pump via a pressure-resistant hose and the outflow port is connected to the downstream pipework. The minimum hose length is 900 mm, with nominal line diameters of less than 18 mm, a length of 600 mm is sufficient. Narrow hose bends should be avoided.

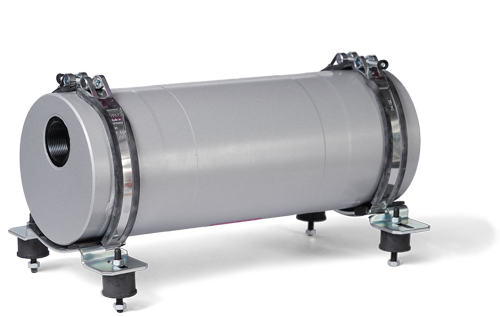

The Hänchen vibration dampers or structure-borne sound absorbers are supplied with attached elastic damping feet for fastening.

Technical data of the vibration and structure-borne noise dampers

Damping noises in hydraulic lines

Temperature: - 20 °C to + 200 °C

Flow resistance: < 1 bar

Media: Mineral oil, Niro version on request

| Flow rate [l/min] |

Pressure (bar) |

Outer-Ø (mm) |

Length (mm) |

Port | Weight (kg) |

| 30 | 160 | 320 | 60 | 70 | 235 | 265 | G ½ | G ¾ | 2,5 | 5,5 |

| 80 | 160 | 320 | 95 | 108 | 320 | 370 | G 1 | G 1 ¼ | 7,7 | 17 |

| 200 | 160 | 320 | 160 | 180 | 415 | 474 | G 1 ½ | 26 | 55 |

| 400 | 160 | 320 | 200 | 236 | 475 | 535 | G 2 | 43 | 110 |

Note

Vibration absober and structure-borne noice dampers are not suited for the damping of shifting or acceleration impacts in hydraulic systems or for the damping of vibrations, which are caused by vibrating non-return valves, undamped overpressure valves etc.