Rods, shafts, axes

small batches and unique single pieces

- component parts with large diameters up to 200 mm

- unique single pieces and small batches

- high surface accuracy

- various production technologies from one source

Properties.

Rods, shafts, axles.

In our machining centres, we can produce individual pieces or small series with up to Ø 600 mm and a length up to 400 mm. Our lathes can machine up to Ø 200 mm and a length of up to 3,500 mm.

- Material quality

High-quality steel materials such as 20MnV6, 42CrMo4V, 16MnCr5, stainless steels such as 1.4571 or 1.4462, but also aluminium alloys or non-ferrous metals are the raw material for the production.

- Design and engineering drawing

- We are happy to take over the development and design for your individual machine element or manufacture according to your model. We use modern methods such as FEM calculations and CAD/CAM.

- Coating

Anodised aluminium, hardened steel, hard-chrome plated or nickel plated – as your application requires. Bronze and synthetic layers can be fitted as sliding surfaces on the inside and outside.

Design.

We make the rod work.

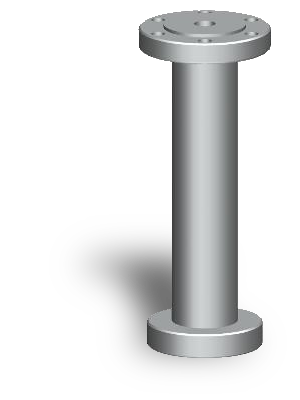

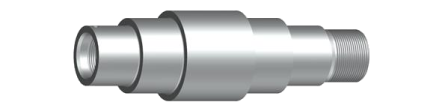

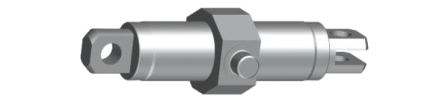

Be it precision shafts, axes, guide pillars, or piston rods. Integrated holms, guide rods, or pressure-resistant distributors for fluid supply under high pressure.

- Precision shaft

No matter what type of ends you want for your shaft or rod – we have what you need: male threads, female threads, pins, cylindrical or cone-shaped shaft seats, radial bore or feather key groove, with wrench flats, square or hexagonal.

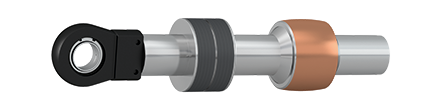

- Functional rod

Connecting rods and piston rods with round or rectangular flanges, shafts with plates. One-piece, or welded in the middle or on the end. Even trunnion flanges with their special geometry are no problem for us.

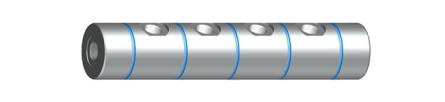

- Distributor axle

High-pressure resistant fluid distributors, with transverse and longitudinal bores. With pipe threads or cone-shaped threads for direct connection to the supply line. If necessary, they come with appropriate sealing elements for direct installation in your machine housing.