Airplane wing test stand for simulating the airstream

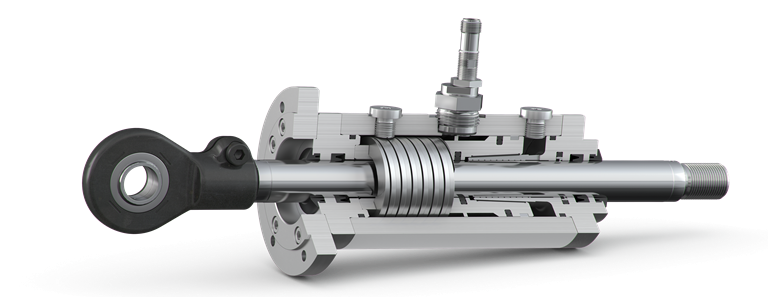

Low friction hydraulic cylinder, clamping unit

Airbus - this name stands for the highest safety standards as well as for a network of European sites that share research, development and manufacturing. To ensure such a level of safety, extensive simulations and tests take place. System tests that also simulate loads and environmental conditions in different flight phases are particularly demanding. In this project, the landing flaps and slats are tested.

Since the forces involved are rapidly changing with very irregular parameters, the actuators simulating the airflow have to meet the highest requirements. This is why Airbus Bremen decided to purchase the 26 low friction servo hydraulic cylinders for the new test stand from Hänchen. In addition, there were 8 clamping units for safeguarding the test stand.

- Long service life of the products

- Optimum friction performance

- Reliable and precise reaction

- Competent advice, also via videochat

Technical requirements

- Control deviation of 1 % with static load and 4 % with dynamic tests

- Minimum movements up to 0.02 m/s

- Maximum movements up to 1 m/s

- Safety element to protect the operating personnel and the test stand

Technical realisation

- Hydraulic cylinder series 300 in Servocop® design

- Bore between 40 and 160 mm

- Rod Ø between 30 and 110 mm

- Stroke from 300 to 1,670 mm

- Clamping units Ratio-Clamp®

- Holding force between 140 and 300 kN

Implementation

Use of the test actuator

The high lift divide system

An absolutely thorough test

Hydraulics simulate air loads

_Retusche.jpg?m=1690201878)

.jpg?m=1690201926)

.jpg?m=1690201964)

A350 XWB – the latest project

Cover type Servocop®

The design of the high lift test stands

Cross section of a Ratio-Clamp® clamping unit with a Servocop® sealing system

Cross section of a Ratio-Clamp® clamping unit with a Servocop® sealing system

Clamping unit Ratio-Clamp®

To fix the hexapods securely even without applied pressure for an unlimited period of time, all hydraulic cylinders feature a flanged clamping unit Ratio-Clamp® on the flaps. This patented clamping is designed for a holding load of between 140 and 300 kN, depending on the cylinder. The force is stored in screw plate springs and fixes the rod via a conic clamping element through frictional contact in case of pressure loss. The applied spring sets and the length of the cone exactly define clamping force and trigger pressure here. This clamping procedure can be triggered by direct cut-off, reduction of pressure or a power failure as well as system damages. This clamping force is then preserved for any amount of time without energy supply until the releasing pressure is applied again and the piston rod thus released. In case of applied pressure, the rod can be turned in both directions with low friction. The use of Ratio-Clamp® also provides the typical advantages of a hydraulic system: high power density and precise reaction due to the minimal compressibility of the fluid. This practically rules out damage on the expensive Airbus test stands, for example in case of a failure of the hydraulic supply.

Hänchen is a must in Bremen

"We like to work with Hänchen cylinders and clamps, because they have proven themselves well and maintain the promised quality," summarised the leading test engineer Johst. "We have gathered this experience since our first high lift tests in 1980. Even though we work in many sectors with several partners: Hänchen products are a standard in our company."

Jörg Beyer, mediaword

© Hänchen 2013