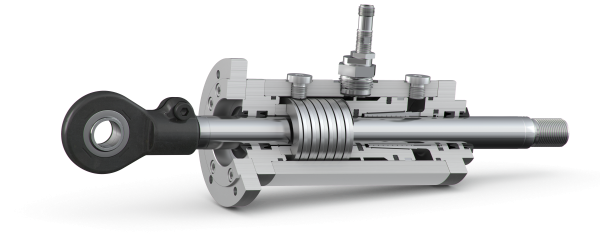

Safety rod lock for hydraulic presses, injection moulding machines, …DGUV Test-certified hydraulic clamping unit Ratio-Clamp®

Featuring a particularly high safety reserve and, the hydraulic cylinder clamping rod lock unit certified by DGUV Test are approved for the use in hydraulic presses according to EN ISO 16092-1/-3, and in plastic injection moulding machines according to EN ISO 20430. They meet all requirements of the DGUV Test, the testing and certification authority for safety cylinder rod lock, lifting gear, safety components and machinery.

- the holding forces are at least twice the weight of the load to be carried.

- the locked status is sensed by an inductive proximity sensor and displayed. The sensor operates without making contact and is thus practically free from wear and tear.

- the proximity sensor is equipped with an additional diagnosis output to enable it to monitor its own functions.

- the rod clamping unit is intended to be used to lock during a machine downtime.

- safety rod lock is activated in case of a power failure

- approved by DGUV Test

- no damage to the clamping device

- no damage to the clamped rod

Installation instructions for hydraulic clamping system for personal security

Next to the providing the user with the catalogue range of products we at Hänchen are only too glad to offer our know how and experience with regard to hydraulic clamping systems for a safety rod lock in their planning and configuration.

Use as a safety element

The clamping unit is a reliable technological rod lock solution if hazards due to external forces or loads must be taken into account in accordance with EN ISO 13849-1. In case of fluctuations or loss of the pressure energy, the clamping unit immobilises round rods under an axial load.

For more information about the functional principle, please refer to clamping device basics.

As a safety element, the clamping unit is used as follows:

- As a secure position retention element in case of a line break

- As a locking element if cylinders or valves have internal leakages, e.g. through gap seals

- As an additional safety component for axes strained by gravity, if the load causes hazards, e.g. in hold-up devices when lowering a load associated with hazards

The clamping unit, with its frictional contact function, is permitted as a redundant safety component in accordance with EN ISO 13849-2. For example, a non-return valve can be used as a primary safety element.

Technical data of hydraulic clamping device

- for all round rods with hard surfaces

- load capacity independent of direction

- after 1 million switching cycles the Ratio-Clamp® shall be inspected at the factory

- max. rod speed: 1 m/s with Servocop®, 2 m/s with pressure piston seal

- max. releasing pressure: 160 bar

- working temperatures: -30°C bis +80°C

- fluids: mineral oils, others like water, HFC or Skydrol® on request

| RATIO-CLAMP® |

RATIO-CLAMP® AS SAFETY COMPONENT |

||||||

| + Releasing pressure + Locking + Sealing system + Certification |

Basic design With spring power Servocop® TÜV |

Basic design With spring power Servocop® TÜV, DGUV Test |

|||||

| Rod Ø (mm) |

Max. holding load (kN) |

Releasing pressure min. (bar) |

Max. holding load (kN) |

Permissible load according to DGUV Test (kN) |

Releasing pressure min. (bar) |

||

| 16 | 10 | 60 | |||||

| 18 | 12,5 | 55 | 12,5 | 6,25 | 55 | ||

| 20 | 14 | 55 | 14 | 7 | 55 | ||

| 22 | 17 | 70 | 17 | 8,5 | 70 | ||

| 25 | 20 | 70 | 20 | 10 | 70 | ||

| 28 | 31,5 | 90 | 31,5 | 15,75 | 90 | ||

| 30 | 40 | 105 | 40 | 20 | 105 | ||

| 32 | 40 | 60 | 40 | 20 | 60 | ||

| 36 | 45 | 75 | 45 | 22,5 | 75 | ||

| 40 | 50 | 80 | 50 | 25 | 80 | ||

| 45 | 65 | 70 | 65 | 32,5 | 70 | ||

| 50 | 80 | 90 | 80 | 40 | 90 | ||

| 56 | 90 | 75 | 90 | 45 | 75 | ||

| 60 | 100 | 75 | 100 | 50 | 75 | ||

| 63 | 100 | 85 | 100 | 50 | 85 | ||

| 70 | 140 | 80 | 140 | 70 | 80 | ||

| 80 | 180 | 90 | 180 | 90 | 90 | ||

| 90 | 200 | 65 | 200 | 100 | 65 | ||

| 100 | 250 | 75 | 250 | 125 | 75 | ||

| 110 | 300 | 65 | 300 | 150 | 65 | ||

| 120 | 330 | 70 | 330 | 165 | 70 | ||

| 125 | 350 | 75 | 350 | 175 | 75 | ||

| 140 | 450 | 65 | 450 | 225 | 65 | ||

| 160 | 750 | 90 | |||||

Other holding forces and rod Ø on request.

Hydraulic locking is possible up to 2,000 kN holding load and 300 mm rod Ø.

The stated values apply to operation with mineral oil. The holding load may differ when using other fluids.