Hydraulic complete solution in a rolling mill

Drive system Ratio-Drive®, industrial hydraulic cylinder, clamping device

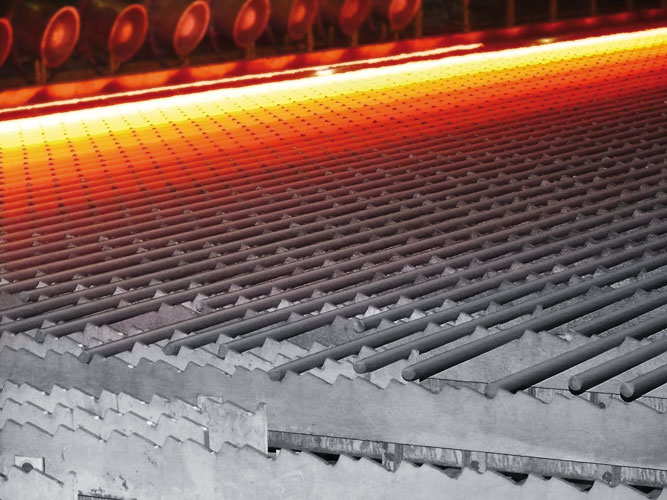

At 12 m/s, the redhot steel rods are transported out of the finishing roll block onto the cooling bed of the rolling mill of Georgsmarienhütte (GMH). Start-stop shears cut the rolled strands to cooling bed length. The braking process and transfer of the rolled strands from longitudinal direction to the diagonal transport of the cooling bed is performed by deflectors, separating devices and the brake calliper.

The functional reliability of these processes essentially depends on the precise interaction of the individual technical assemblies. The entire handling of the rolled strands is performed in a dynamic process in which the cooling bed rakes take over the rolled strands in the end.

Here, a hydraulic solution by Herbert Hänchen GmbH & Co. KG from Ostfildern near Stuttgart generates synchronous linear movements with a low-wear and low-maintenance design and technology. This positions the rolled strands reliably. This complete drive system solution comprises the entire implementation process ranging from the system design, the production and the procurement of the hardware up to commissioning.

- Hysteresis towards 0

- No expensive system downtimes

- High control accuracy

- Material-friendly interaction of all components

- 160 mm movement length

- 12 tons of moving mass

- Synchronous at +/- 1.5 mm

- 1.4 seconds cycle time

- Hydraulic engineering advice and GC for the implementation of the drive system

- Programming of customer-specific sequence control

- Replacement of the original electrical solution with a hydraulic solution with the aim of significantly minimizing maintenance intervals and abrasion

The challenge

move 12 tons every 1.4 seconds

A brake calliper moves the at most 40 metres long rods to the side toward the cooling bed. The subsequent rolled rod moves at the same speed next to the cut rod. As soon as this rod stops moving, it is lifted into the rake cooling bed. The new rolled rod, which is still red hot, is also transported toward the cooling bed via the brake calliper. This tilting process requires a lot of force: Within 1.4 seconds, the brake calliper has to move a load of up to 12 tons consisting of components and rolled rod. Three hydraulic cylinders synchronously perform a motion over 160 mm at high acceleration, mass and speed with an accuracy of +/- 1.5 mm. This process is realised by Ratio-Drive®, a complete linear drive solution made by Hänchen. Three industrial hydraulic cylinders that replace the previous electromechanics form the hardware basis. Maintenance intervals and wear can thus be significantly reduced. In 2006, GMH changed the technology to hydraulics. For Dr. Jürgen Wagner, maintenance and mechanical engineering team leader, it was not only important to receive hardware, but to also develop a completely new technological solution together with Hänchen. In this process, "Hänchen provided the know-how for the entire system integration."

The Ratio-Drive® application replaces an electromechanic design. This put a severe strain on the components due to the inflexible sinusoidal motions and the "hard" start-up and control behaviour of the drive specified by an eccentric. Add to this the oscillation strain caused by constant adjustment. The consequence was a corresponding material fatigue on a large number of connection and deflection points. The strain became even worse because the brake calliper could only be driven via a single servicing point. This resulted in high leverage forces. The electromechanic system consisting of the motor, gearbox, clutch, deflection blocks and eccentric shaft were used to their limits according to the maintenance staff. This is why GMH decided to replace the mechanical system with a hydraulic one.

A complete solution

hydraulics, electrics, software

The complete solution provided by Hänchen ranges from the industrial hydraulic cylinder up to the self-developed and readily configured controller programming, hydraulics, electronics, software, data processing and engineering, meaning the entire hydro-mechatronics. Industrial hydraulic cylinders are Hänchen's core business in production. GMH uses industrial hydraulic cylinders in the so-called Sevocop® design. This standard series is equipped with an integrated position transducer and pressure transducer. It is an especially low-stick-slip, has a low breakaway torque, a sensitive response behaviour and an especially good reproducibility of movements, is friction-optimised and leakage-neutral. These industrial hydraulic cylinders are extremely sturdy and designed for speeds of up to 1 m/s. Despite these performance characteristics, the Servocop® design is much less expensive than the high-end types Servofloat® and Servobear®. With both of the latter ones, Hänchen can realise standard speeds of up to 4 m/s in other applications, frequencies of up to 500 Hz with controlled curves and forces of up to 9 MN at a positioning accuracy of a few μm. Special constructions achieve even higher performances.

For GMH as client, the main task was the system integration and engineering: Programming a material-friendly interaction of all components was just as decisive as the precision of the synchronisation. Especially challenging in this respect were the high masses, the extreme acceleration, the multifarious positive couplings and the mechanical interactions partially due to the play of the components caused by thermal conditions. This is why the fine tuning was performed on the running system.

Hänchen as prime contractor

for a complete drive system

Multifarious third-party products such as valves, piping, electrics, electronics, measuring systems and computers were also applied in this solution. In this situation, GMH only had one responsible contact - the Swabian hydraulic specialist. The Ratio-Drive® complete system forms a contained system that receives external target value specifications and realises linear movements. In addition, it had to be integrated in the system control, and cabling and piping were also tasks that had to be implemented by the Ratio-Drive® developers. The hydro-mechatronics by Hänchen only receives the position specifications via a profibus interface here: "Pick-up" (0 mm), "Transfer" (160 mm) and "Initial position" (100 mm). In this initial position, the industrial hydraulic cylinder is fixed in position for any period of time even without hydraulic pressure with the hydraulic clamping device Ratio-Clamp® made by Hänchen. In this process, the plate springs apply the holding load to a round rod via a cone until the defined release pressure is once again applied to the hydraulics. This ensures permanent fixation in any shut-off state.

Software and real-time computer

for a precise motion sequence

After triggering the motion through a new position specification, the realtime computer system implemented by Hänchen as a component of the Ratio-Drive® calculates the precise motion sequence in connection with the Ratio-Drive® software. For us, the peripheral control is quite a change because of working with a independent subsystem," says Burkhard Schmidt, team manager of electric maintenance. "Due to the accuracy in the synchronous run control, we have opted for an independent system, which Hänchen has completely designed, taken responsibility for and integrated. ISIS, our partner for the control system, was the sub-supplier, which made Hänchen the prime contractor." The integrated position transducers in the three industrial hydraulic cylinders provide the actual values of the closed control circuit and report these to the control system via the bus. However, how the industrial hydraulic cylinders reach their position synchronously and with as little mechanical strain as possible is an internal task of the Ratio-Drive® software. It is based on a module system that the Swabian software developers have constantly expanded and optimised over the years. Add to this the individually programed customised sequence control at GMH. The only integrations are the bus as electronic interface, the three interaction points on the calliper as mechanical interfaces and the electric energy supply. The entire Ratio-Drive® therefore performs the function of a black box integrated in the system.

Hysteresis tends towards 0

In the context of this black box concept, the industrial hydraulic cylinders perform a motion at which the force and the speed can be adjusted at any time. This allows defining the acceleration for each motion segment within further limits, which minimises material wear due to the acceleration curves optimised by the system. Friction losses due to contamination and other faults also play only a minor role. The system is able to compensate influences caused by higher pressure in many situations, and possible faults can be rectified at the next maintenance. Costly standstill times of the system are avoided. But the main advantage is the low hysteresis: "The hysteresis tends towards zero," sums up Dr. Wagner. "This way, we always cover clearly defined positions." The complete drive system created with the system competence of GMH maintenance and the hydro-mechanical expertise of Hänchen has proven its efficiency over the past two years. And that's not enough: "Further future projects are already in the planning phase."

© Hänchen 2011