Test stand for seals and rod surfaces

Servo hydraulic cylinder

To determine the characteristic values of a seal, seal test benches are suitable for simulating a wide range of operating conditions. The focus is often on the frictional force of the seals, tightness on rods and shafts, temperature performance and wear.

"It all began with the fact that seals for our own hydraulic cylinders had to be tested efficiently and under realistic conditions", says Dipl.-Ing. Klaus Wagner, Head of Development at Herbert Hänchen GmbH. Meanwhile, the company from Ostfildern near Stuttgart designs and produces test stands for the examination of seals in the research and industrial sectors. The individual test stands are realised electrically or hydraulically, depending on the requirements of the seal manufacturer.

This is why customers choose Hänchen:

- Own experience in testing of seals

- Comprehensive advice

- Individual concept

- Implementation of only required functions saves costs

Figure 1 Protective fence as a technical safeguard

Figure 2 Individual seal test up to the test procedure of the seal combination at Hänchen after 300 km of use in 24-hour operation.

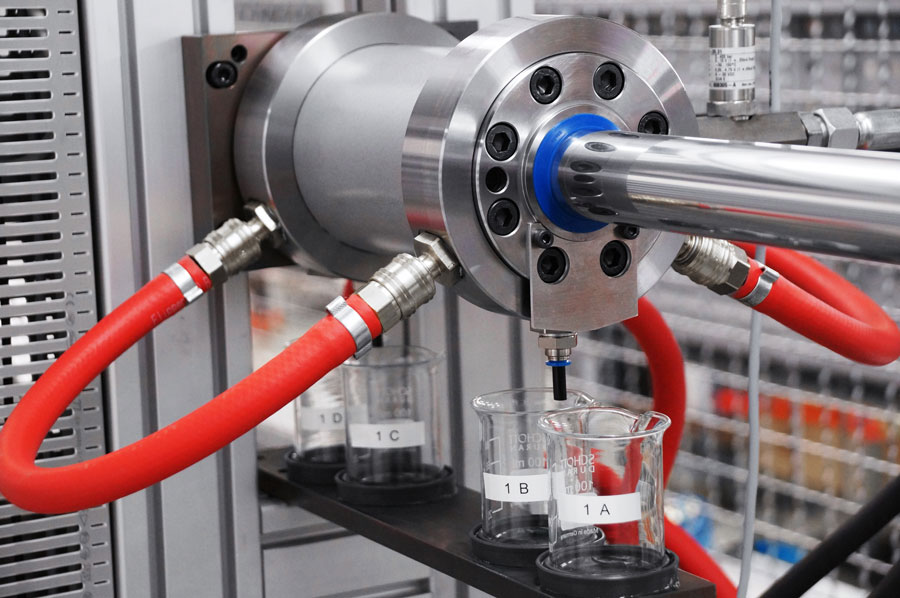

Figure 3 Four hydraulically operated test axles, each of which tests two test chambers with defined sealing combinations.

Requirement testing machine

- Complete test machine compliant with Machinery Directive

- 4 axles, each with 2 test rods, which can be moved independently from each other

- Fatigue test 24/7 covering 300 km

- Measuring wear of rod surfaces and seals

- Friction force determination according to VDMA 24577

- Determination of tightness of individual seals and seal cascades

- Checking of stick-slip behaviour

Technical implementation and solution

- 8 pressure chambers, pressure adjustable up to 600 bar

- Water cooling for constant temperature in the test chambers

- Separating protective device

- 4 double-rod cylinders, series 300, Servocop®, 50 / 40 / 650

- Force transducer on test rods for friction force determination

- Individually adapted software

- Safe control on Beckhoff system

Parameters of the test rig

Test stand construction

"We want to offer our customers optimum sealing combinations through systematic trials", says Klaus Wagner. "To do so, we combine products from different seal manufacturers with our own. We have also been cooperating with university research institutions for long years as a developer and manufacturer of hydraulic cylinders. Since we also design and implement Ratio-Drive® hybrid drive systems and subsystems for our customers, it seemed like a logical step to develop the test stand ourselves. We are thus in-house users."

Requirements for the system – numerous parameters

The choice of the sealing element for the piston rod surface is a crucial factor that determines the quality of a hydraulic cylinder and other products that work with fluids. Various, opposing parameters clash in this area. "Tightness and minimisation of friction are actually contradictory parameters," says Matthias Breisch, Head of Testing Department at Hänchen. "That's why, in the past, it used to be either 'tight or free-moving' in hydraulics." Tightness is nowadays a matter of course in quality products. Other important parameters include friction, wear, precision in positioning and repeatability, maximum and minimum speed, stick-slip behaviour, minimum and maximum pressure, suitability for particular fluids, such as Skydrol® or water-based fluids, and fluid contamination limit values. In addition to these, there are also different sealing systems: Classic seals with seal and lip seals, and non-contacting seals with hydrostatically supported piston rod guide or with the floating gap seal, which is, by the way, a Hänchen patent. In the case of classic seals, the various sealing materials play just as much a role as the geometry - in particular that of the sealing edge. However, even the nature of the counterface, such as that of the piston rod, and the friction and lubrication properties of different fluids are decisive factors. These include chromium-plated steel or light metals, but also modern materials with a special synthetic coating such as H-CFRP® – Hänchen's proprietary carbon composite material. The surface processing methods of these materials (e.g. honing or grinding) also have an influence on the sealing effect.

Mechanical implementation – multiple test stand

The system, which was presented to the specialist public at the end of 2015, has now completed its trial phase. At the heart of this technology, there are four hydraulically operated test axles, each of which tests two test chambers with defined sealing combinations. All four axles can be operated with different types of test specimens and parameters. The system's stroke is freely selectable, depending on the rod. Speeds up to 4 m/s can be achieved. During stand-alone parallel operation, all 4 rods can be moved up to 1 m/s and the frequency can be up to 5 Hz.The seal test stand also allows the execution of tests in accordance with VDMA 24577 to identify the friction force. The pressure in the test chamber can be set up to 600 bar and adjusted during movement to enable mapping of realistic conditions. The motion profile is designed for sinusoidal or constant speeds. The acceleration phase can also be configured. Any rod with any combination of seals can be treated as a test specimen and tested with a wide variety of fluids.

Data collection and evaluation – measuring, controlling, regulating

The special Hänchen software controls the test process, test sequence and the evaluation of the measured variables. Thanks to individual programming on Beckhoff systems, the user can control the test axles individually and run different motion profiles. The servo hydaulic test actuators are equipped with force transducers and position transducers for measurement and high-precision control. The friction force of the sealing systems is determined on the test stand, depending on the parameters measured online: Test chamber pressure, test chamber and piston rod temperature, and the position or movement profile (e.g. speed). In order to achieve the most uniform result possible, the test seals can be cooled. During particularly sensitive tests, it is also possible to use a hollow-bored rod to cool it. To enable precise documentation and optimal test evaluation, the Ratio-Drive® software records the data on an industrial PC. This gives the user the opportunity to assess the measured variables recorded in the test stand either by means of the integrated evaluation tools or using any other evaluation software, such as Diadem.

Manual devices measure the tightness of the primary seal and the entire sealing system to the outside. The evaluation also includes the displacement patterns on the rods and checking the individual elements of the sealing system with respect to wear.

Manual devices measure the tightness of the primary seal and the entire sealing system to the outside. The evaluation also includes the displacement patterns on the rods and checking the individual elements of the sealing system with respect to wear.

Standard test procedure for sealing systems

Hänchen's internal test cycle for a sealing system consisting of a rod and seal combination generally covers 300 km of use in 24-hour operation. Extensive tests of recent years have proven the effectiveness of bronze-filled PTFE seals as the primary seal in combination with a secondary seal and a wiper ring. Hänchen implements this concept in its servo hydraulic cylinders via the Servocop® sealing system – a tried-and-tested combination of a compact seal, lip seal and wiper ring. "When we combined these items together, it turned out that products from different manufacturers delivered very different results despite being made of the same materials." Matthias Breisch describes a very special achievement: "The cross-manufacturer combination of elements gives results that vary by up to 50%. This does not mean that a seal alone is better or worse, but rather that the compatibility of the sealing elements with each other and with the counterfaces is of crucial importance."

Tests have proven the effectiveness of honing as fine machining of rod surfaces to achieve the lowest possible friction together with an excellent distribution of lubricants. They also showed that short-stroke honing further optimises the surface, while ground surfaces have a rather unfavourable effect on the performance and service life of seals. Honing also manages to achieve a correspondingly high-performing surface even on the H-CFRP® material.

Tests have proven the effectiveness of honing as fine machining of rod surfaces to achieve the lowest possible friction together with an excellent distribution of lubricants. They also showed that short-stroke honing further optimises the surface, while ground surfaces have a rather unfavourable effect on the performance and service life of seals. Honing also manages to achieve a correspondingly high-performing surface even on the H-CFRP® material.

Custom seal test stand

Hänchen implements comparable test machines for customers such as the University of Stuttgart and has long years of experience as a manufacturer of drive systems. Within the framework of a Ratio-Drive® project, it is possible to manufacture seal test stands specifically to customer requirements. Thanks to a modular design and the use of tried-and-tested software, it is possible to save on costs and minimise prototype-related risks. The customer receives all mechanical components from a single source – from the drive and the integrated pressure/position transducers to the construction. Hänchen works hand in hand with the customer to define the safety concept of Ratio-Drive®'s perimeter in accordance with the requirements of the Machinery Directive 2006/42/EC. The requirements for machine controls according to EN ISO 12100 and in particular the assessment of machine-induced risks according to EN ISO 13849-1 are considered up to performance level PLe, depending on the requirements.

In-house application from the concept right through to the complete test machine and the daily use give peace of mind to the various customer groups.

In-house application from the concept right through to the complete test machine and the daily use give peace of mind to the various customer groups.

Jörg Beyer, mediaword

© Hänchen 2017

© Hänchen 2017