Servo hydraulic actuators

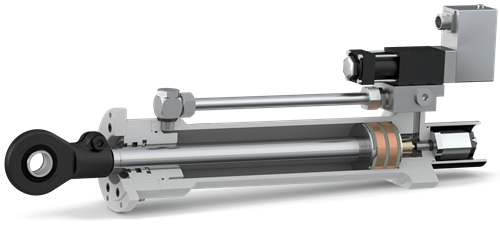

Hydraulic servo actuators with valves and sensor technology

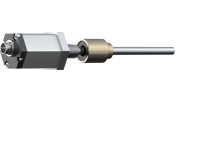

High speeds, frequencies, accelerations: Hänchen hydraulic servo actuators in the 120 and 300 series with integrated position transducers always keep up.

Hänchen high quality hydraulic cylinders fulfil highest technical requirements with harmonized sealing elements, for a safe and reliable drive control.

Read more about Servo hydraulic actuators for test systems.

- optimal price/performance ratio

- suited for test tasks with long strokes

- as single-rod or double-rod servo cylinders

- with integrated position transducer

- low dead weight

- optional mounting plate for control valve

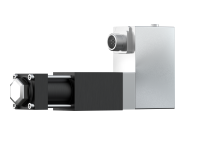

Sensor technology and valves for servo hydraulic actuators

Perfect for dynamic industry and test tasks

For the necessary sensitivity, Hänchen offers convenient sensor technology components and valves – all for highly dynamic, precise drives with high energy density.

To operate the drive in an Industry 4.0 environment, sensors can also provide data for condition monitoring:

• Pressure transducers in the chambers analyse the friction behaviour

• Temperature and colour sensors provide information on the condition of the fluid

• Online particle counters indicate the degree of contamination of the system

• Flow sensors on the functional oil channel indicate the need for a seal change

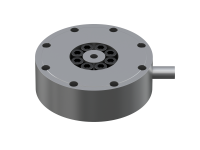

Hänchen hydraulic servo actuator series

For controlled movements

- Servo actuator series 120

- bore 40 mm to 180 mm

- working pressure up to 150 bar

- as single-rod cylinders

- round-head cylinders according to ISO 6020-1

- various mounting methods

- honed and chrome-plated piston rod

- test pressure = 1.5 x max. working pressure

- Servo actuator series 160

- bore 50 mm to 125 mm

- working pressure up to 160 bar

- as single-rod cylinders

- round-head cylinders according to ISO 6020-1

- various mounting methods

- honed and chrome-plated piston rod

- test pressure = 1.5 x max. working pressure

- Servo actuator series 300

- bore 50 mm to 140 mm

- working pressure up to 300 bar

- as single-rod or double-rod cylinders

- round-head cylinder design

- various mounting methods

- honed and chrome-plated piston rod

- test pressure = 1.5 x max. working pressure

- Test actuator series 320

- Bore from 28 mm to 320 mm

- Working pressure up to 320 bar

Hydropulsers are ideal for highly dynamic applications. Find out more about this on the hydraulic test actuator page.

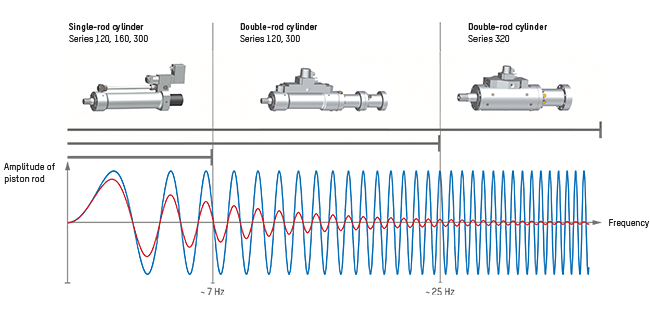

Suitability of cylinder series according to frequency range

The required dynamics of the drive determine the cylinder's type of effect. When fast control valves are used, even single-rod cylinders achieve a high profile quality at high frequencies.

The limit values shown in the diagram are intended as guide values for your design. They depend on various operating conditions – we can help you make the right choice

Servo cylinder configurations

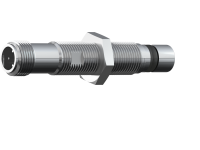

Sealing and guiding systems

The sealing system in the cover and on the piston is the heart of a hydraulic cylinder and determines the possible applications. With these you determine the sensitivity of the servo cylinder movement, the minimum amplitudes which can be travelled and the effect of side loads. You can also choose low-wear sealing systems.

We recommend using the synthetic guide Servoslide® or PTFE wear rings as a guiding system in the cover for servo cylinders that operate in an oscillating manner.

Here you can learn more about the cover and piston equipment in the hydraulic cylinder.

Accessories and equipment for servo cylinders

Mounting elements, assembly tools and tools

In the online product configurator HÄKO, you can find our standard accessories and equipment to match your chosen cylinder.

Type of effect: single-rod cylinder, double-rod cylinder* | Sealing systems: basic design, Servocop®, Servoseal®*, Servofloat® |

Speeds: up to 2 m/s | Stroke: 1 - 1,500 mm

| Series 120 150 bar** |

Series 160 ISO 6020-1 160 bar |

Series 300 300 bar |

|||

| Bore (mm) |

Rod Ø (mm) |

Force F1 | F2 (kN) |

Force F1 | F2 (kN) |

Force F1 | F2 (kN) |

|

| 40 | 25 | 18.8 | 11.5 | --- | --- | |

| 50 | 25 28 30 40 |

29.5 | 22.1 --- 29.5 | 18.8 --- |

--- 31.4 | 21.6 --- --- |

--- --- 58.9 | 37.7 58.9 | 21.2 |

|

| 60 | 30 40 50 |

42.4 | 31.8 42.4 | 23.6 --- |

--- --- --- |

--- 84.8 | 47.1 84.8 | 25.9 |

|

| 63 | 36 | --- | 49.9 | 33.6 | --- | |

| 80 | 40 45 50 60 |

75.4 | 56.5 --- 75.4 | 45.9 --- |

--- 80.4 | 55.0 --- --- |

--- --- 150.8 | 91.9 150.8 | 66.0 |

|

| 100 | 50 56 60 80 |

117.8 | 88.4 --- 117.8 | 75.4 --- |

--- 125.7 | 86.3 --- --- |

--- --- 235.6 | 150.8 235.6 | 84.8 |

|

| 125 | 60 70 80 100 |

184.1 | 141.7 --- 184.1 | 108.7 --- |

--- 196.3 | 134.8 --- --- |

--- --- 368.2 | 217.4 368.2 | 132.5 |

|

| 140 |

80 |

230.9 | 155.5 230.9 | 113.1 |

--- |

--- 461.8 | 226.2 |

|

| 160 |

80 |

301.6 | 226.2 301.6 | 183.8 |

--- |

--- --- |

|

| 180 |

100 |

381.7 | 263.9 381.7 | 212.1 |

--- |

--- |

|

* Not for serie 160

** When pivot mounted, the pressure is limited to 120 bar.

F1 = Compressive force while the cylinder is extended | F2 = Compressive force while the cylinder is retracted

With double-rod cylinders, retraction and extension corresponds to the value F2.