Hydraulic linear drive in punching machines and test stands

Custom hydraulic cylinders as self-contained servo drive

You found what you were looking for: When Voith Turbo H + L Hydraulic were looking for a reliable and competent partner for the cylinder of their CLDP hydraulic linear axis, as a supplement to their own cylinder program, they found Hänchen's hydraulic specialists to be the best option to expand their expertise in the field. The extensive experience with high-performance seal combinations, the flexible production of unique single pieces and small batches, and the range of cylinders with variable bore were all very important for this project.

"Voith approached us with this project request, which led to a very close cooperation," sums up Managing Director and Sales Manager Stefan Hänchen. "Because in the required areas, we have decades of experience."

- We minimize your prototype risk considerably with our extensive experience in the design of hydraulic cylinders.

- Our flexible manufacturing structure enables us to produce both series cylinders and special cylinders efficiently.

- Leak-tightness: no possibility of refilling oil in this closed circuit

- Long service life: long maintenance intervals for the self- contained servo drive

- No stick-slip: low static-sliding friction for optimum efficiency

- Reliable in the coordination between the design engineers

- Flexible in the realisation of special adaptations

- Demand for high product quality

Hydraulics as a complete system

The hydraulic plug and play solution

The name CLDP stands for 'Closed Loop Differential Pump' by Voith in Rutesheim and is a servo drive with integrated pump. This means that this hydraulic drive must be only connected mechanically, electrically and electronically and then operates maintenance-free for a period of 3 years or 20,000 hours. Voith supplies the complete package, which has a drive element using a hydraulic cylinder by Herbert Hänchen GmbH. It enables both the operator and the manufacturer of machines and systems to use high-performance hydraulics, even without knowing much of hydraulics – and all this in a valveless system with optimum efficiency. "Especially when it comes to large forces, the spindle drive is no match for the hydraulic cylinder. Besides providing easier handling of large forces, it also exhibits much less wear", explains Dipl.-Ing. Harald Branz, Project Manager and Sales Manager at Voith. "And top energy efficiency can be achieved thanks to the valveless design." But nowadays, many customers are shying away from hydraulics because they no longer have their own specialists. However, the cost-benefit ratio and the high power density of this technology are still unequalled. The CLDP is a high-performance device that the customer can still use without knowing anything about hydraulics.

Hänchen as a strategic partner

Voith was therefore looking for a strategic partner and decided for Herbert Hänchen GmbH, based in Ostfildern near Stuttgart, not only because the company fulfils a variety of requirements with its hydraulic cylinders but also due to its decades of experience in production. "We were looking for a partner who would supplement our knowledge in systems with corresponding knowledge in hydraulic cylinders," says Branz. "We specialise in short-stroke cylinders. Our production facilities are optimally matched to the series production of these cylinders. Hänchen has the right competence for the CLDP and is in no way a competitor. That is why we have jointly optimised the cylinder for the hydraulic linear drive in many areas and combined the strengths of both companies." Voith provides the main specifications that Hänchen then implements. Stefan Hänchen: "We had a strong coordination effort to come up with a common product. The right engineers worked together on both ends." Clearly defined processes were set on both sides in the context of joint development. For a successful implementation of this project, Hänchen contributed with its knowledge in cylinders whereas Voith with its knowledge in systems. The two companies have been working very closely together since mid-2015, with the physical proximity of the two companies being an extra benefit. Branz and Hänchen are both convinced: "This partnership has a future and brings great benefits to our mutual customers."

Hydraulic competence from the manufacturer

Leak-tightness is essential

Hänchen's competence lies in fulfilling Voith's special requirements, which are necessary for the compact drive system:

- Hänchen is known for tightness, accuracy and durability.

- Hänchen has expert knowledge in the use of materials, especially with regard to seals and rods.

- Hänchen makes stick-slip-free cylinders. Sealing combinations and production processes such as special honing methods play a major role.

- In terms of dimensions, Hänchen is flexible in both design and production.

- Hänchen is a specialist known to implement custom adjustments and special requests.

Drives with a specially configured Servocop® seal combination are now a core element of every CLDP. These cylinders can be precisely configured to mm precision even with regard to the bore. The cylinders can therefore offer a precise area ratio of 1:2. Hänchen's production technology also allows the cylinders to be implemented in a square block, which contains the piping in the form of bores and at the same time provides an installation surface for the other elements of the CLDP. Hänchen offers a wide range of standardised cylinders built to a high quality level, which cover a wide range of applications and industries. In the end, this broad knowledge goes mainly to the benefit of the customer. This makes Hänchen an ideal partner for serially produced cylinders that are perfectly matched to the application. By meeting all these requirements, the cylinder offers an excellent price-performance ratio.

Servocop® sealing combination

The Servocop® sealing combination consists of two seals, a wiper ring and a lip seal, largely stick-slip-free. It is extremely tight and does not require a leak oil circuit. All these properties are essential for the closed valve-free fluid circuit, because no refilling of fluid is intended outside the maintenance interval, which stretches over years. The system contains a dedicated accumulator to compensate the fluid volume between the head and cap side. The CLDP can achieve a speed of up to 1.5 m/s at 250 bar system pressure. The Servocop® sealing combination was specially adapted to the specifications of Voith.

A closed fluid circuit

Hydraulics - without the customer's own hydraulic expertise

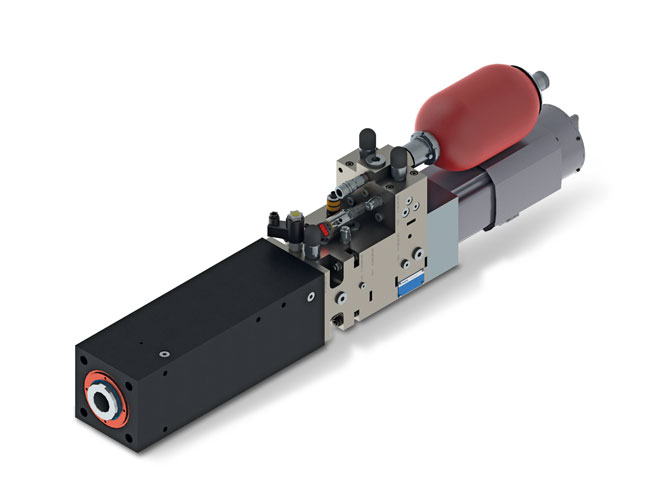

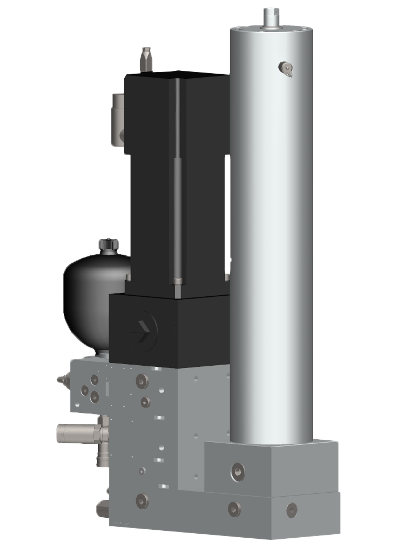

This enabled the creation of a closed fluid circuit. A CLDP servo drive can even be delivered as a physical element for forces up to 500 kN or speeds up to 640 mm/s and with a stroke length of up to 400 mm in the three cost-optimized series with particularly short delivery times. Outside of series production, it is possible to achieve forces of 2,000 to 3,000 kN using this technology. The CLDP is capable of working in temperatures from -5 °C to 40 °C and meets IP 54 or IP 64 requirements, depending on its construction. The CLDP is assembled as a modular system. But the normal bandwidth does not impose a limit on the extensive possibilities: Voith and Hänchen are known for their expertise in custom manufacturing. A much wider range of values is achievable, up to 300 kW drive power of the pump motor. The drive then consists of several individual elements connected by fluid lines under the same maintenance cycle. It can even be used as a closed system in this configuration. The main components of the CLDP are a servo motor, a reduced pulse internal gear pump and a directly coupled hydraulic cylinder produced by Hänchen. The design of the CLDP is self contained and compact. There are three types – linear, parallel and orthogonal – which enable installation in narrow and restricted spaces.

The differential pump

Voith Turbo H + L Hydraulic GmbH & Co. KG has developed a dual unit with two counter-rotating pumps on one axle for such closed circuits and other tasks. To save space, weight and costs, the CLDP works with single-rod cylinders by Hänchen. The differential pump pressurises them with hydraulic pressure. The cap side of the hydraulic cylinder has precisely twice the area of the head side, the flow rate of the two pumps is exactly in the same ratio of 2:1. This defined the requirements for cylinder design and production. At the same time, the vacuum-filled hydraulic axle meets the highest requirements for tightness, minimum stick-slip behaviour and precision. This design provides a linear relationship between engine rpm and position, which greatly simplifies control.

The self- contained servo drive

is based on a servo motor, variable-speed internal gear pumps

and an actuator from Hänchen.

Areas of application

of the self-contained servo drive

The areas of application of the CLDP include bending, cutting and forming machines as well as presses and plastics processing machinery. The dive is generally implemented as an alternative to the spindle drive with servo motor. Further important areas of application include special purpose machines, material handling and the food industry. The CLDP is also used in the testing sector. For all these and many other applications, the CLDP offers the chance of returning to the great advantages of hydraulics – without having to know anything about the subject.

© Hänchen 2017