Painting of hydraulic cylindersThe corrosion protection

At Hänchen, uncoated, metallic components are given a basic corrosion protection in form of a phosphate layer. This layer increases resistance, but also ensures good adhesion of a paint applied to it.

In our paint facility, cylinder tubes, covers and many accessories are additionally given a layer of paint. In this way, we increase the corrosion protection and maintain the product value.

Our standard paint finish

We use a 2K PUR structure paint finish (silicone-free) in the colour RAL 9006, white aluminium semi-gloss. This lacquer is specially designed for mechanically and chemically highly stressed surfaces and has a very high covering power and scratch resistance.

Painted surfaces and components at Hänchen

We paint all surfaces that do not serve as connection surfaces for peripheral components or for connection to the customer's machine or application in order to offer our customers the best possible protection against corrossion.

This means, that among others, the following mounting surfaces, components and screwed fittings - which serve as contact surfaces or have to be opened when the cylinder is mounted in the customer's application - are not painted:

- Sealing surfaces of the ports

- Venting ports and screws

- Fitting diameter

- Spherical and pivot bearings

- Trunnions and flange mounting surfaces

- Piston rods and threads

- Seals such as wiper rings

- Mounting surfaces for valve attachment

- Sensor components

The unpainted, metallic surfaces are provided with an anti-corrosion agent.

Since 01.01.2022, Hänchen has also been painting the covers of the hydraulic cylinders.

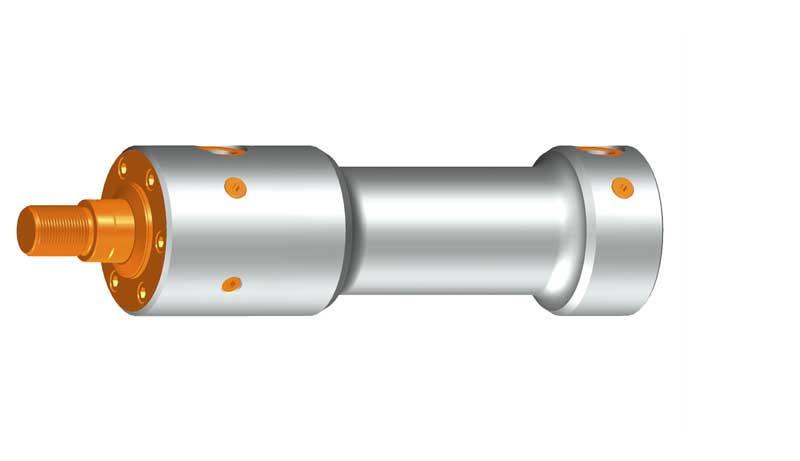

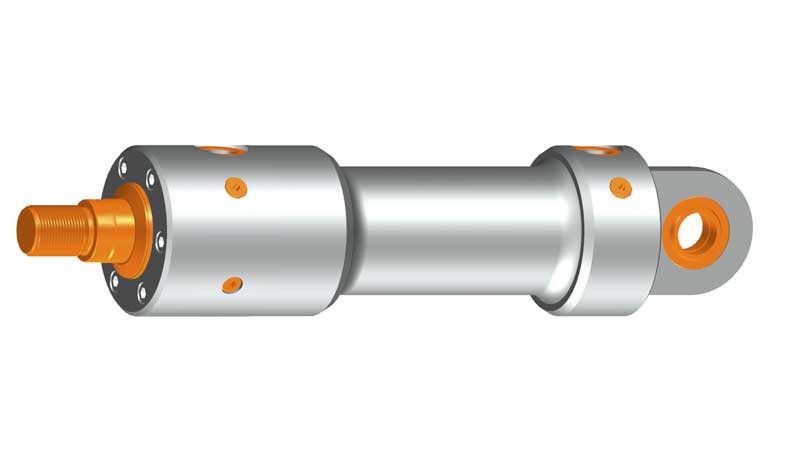

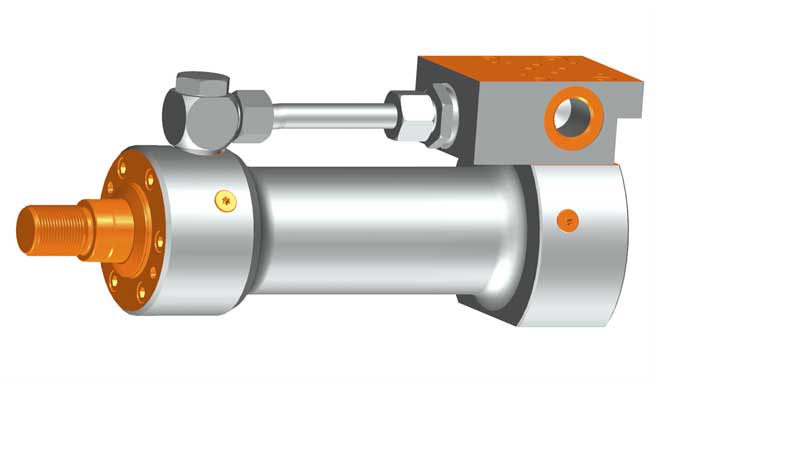

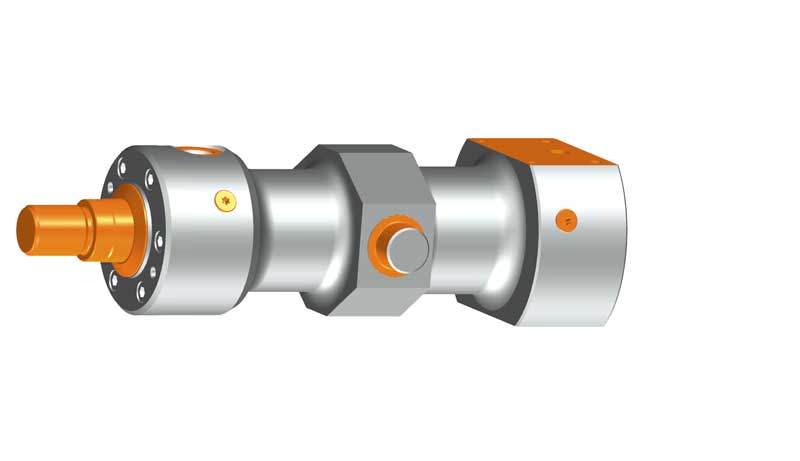

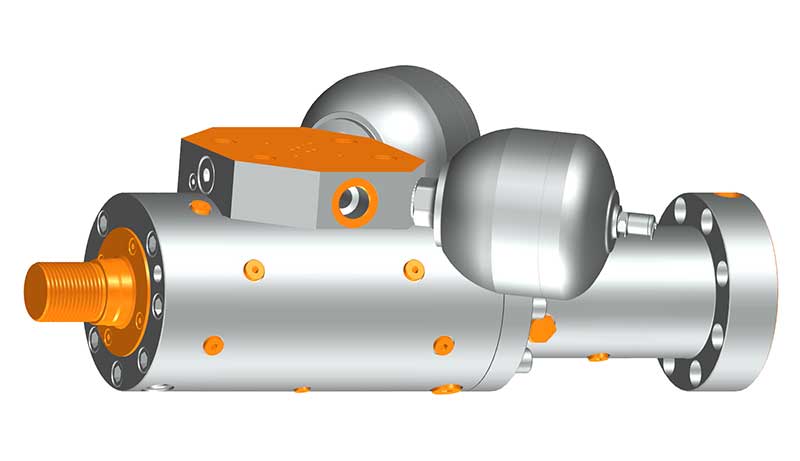

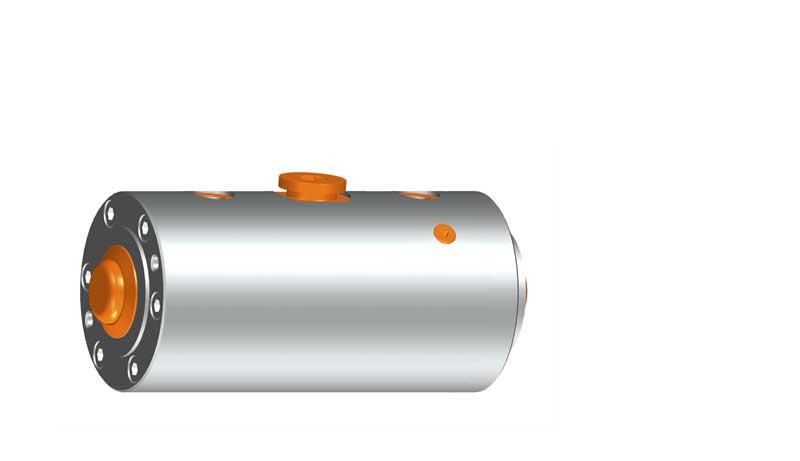

Examples

The orange surfaces are not painted.

Front face* Basic mounting

*in the case of double-rod cylinders, both front faces

Mounting type & fitting diameter

Mounting surface for valve

Mounting surface for mounting plate

Test actuator

Clamping unit

Do you have special requirements for surface protection or painting in general? Feel free to let us know your requirements regarding the application environment, painted surfaces and colour shade in your request.