Servofloat®

Sealing system cover

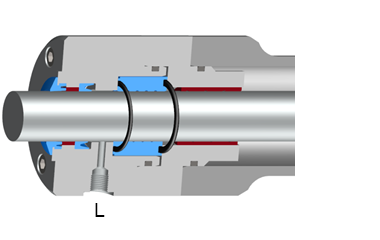

The sealing system Servofloat® in the cover with a floating gap seal is especially suitable for very sensitive and very low-friction movement. The patented floating gap seal makes for a movement with very little stick-slip. Servofloat® is also suitable for highly dynamic movement and oscillations as well as for cylinder loads with high lateral forces.

Function

Due to a narrow throttle gap, the cylinder pressure is relieved to the environment without contact. The floating gap seal's construction-related self-centering makes for a low functional oil flow. The functional oil is discharged to the tank through the functional oil port L.

The contact (functional oil) seal and the wiper ring are not under pressure, which makes for very low residual friction that is constant in the entire pressure area.

Seal combination

- Floating gap seal

- Functional oil seal

- Wiper ring

Depending on the series, the seal materials and the guiding system, this system is suitable for:

| Piston speeds | up to 4 m/s |

| Temperature range | from -30 °C to +100 °C |

The sealing system Servofloat® requires a minimum pressure in the chamber of pmin = 50 bar to ensure centring.

The functional oil shall be discharged into the tank through the functional oil connection without pressure, suction by vacuum is not permissible. Pre-stressing the functional oil line is admissible up to 5 bar.

Serie 320:

Ports for functional oil are internally connected for alternative connection.

All other series:

Connect ports for functional oil externally.

The amount of functional oil depends on the viscosity of the fluid used, the temperature and particularly on the pressure conditions inside the cylinder. Besides, there are several other factors to be taken into account when determining the functional oil flow.

The amounts of funktional oil indicated here have been determined for a fluid ISO VG 46 at 55 °C. However, these can only be used as guide values for the hydraulic calculation; an exact determination of the functional oil flow is only possible by measuring it on the device itself.

|

Functional oil flow Servofloat® |

||

| Rod diameter [mm] |

Functional oil flow min.* [l/min] |

Functional oil flow max.* [l/min] |

| 25 | 0.25 | 0.5 |

| 30 | 0.4 | 0.8 |

| 40 | 0.4 | 0.8 |

| 50 | 0.8 | 1.2 |

| 63 | 0.8 | 1.2 |

| 80 | 1.7 | 3.0 |

| 100 | 2.0 | 3.5 |

| 125 | 7.0 | 9.0 |

| 160 | 7.0 | 9.0 |

* The functional oil flow indications for Servofloat® apply for a chamber pressure of 210 bar (working pressure) for one chamber.