Movement

Proposal for the selection of hydraulic cylinder

The proposal for the selection of equipment features depend on a number of operating conditions.

The correct equipment is crucial for the hydraulic cylinder's quality and reliability, its friction force and its wear behaviour.

Beside the operating temperatures and the travelling distances and speeds determined in the hydraulic design, especially the type of movement should be considered:

|

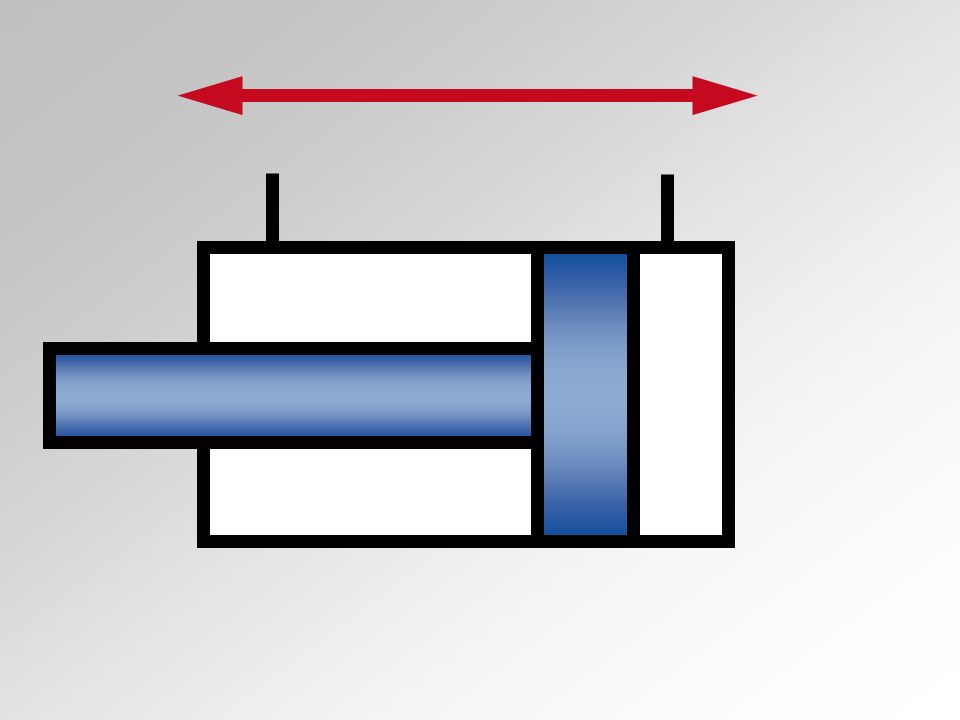

Simple movement If the cylinder movement is controlled via control valves or if the course of movement is subordinate. The sealing system lip seal-wiper ring is recommended for such cases. |

|

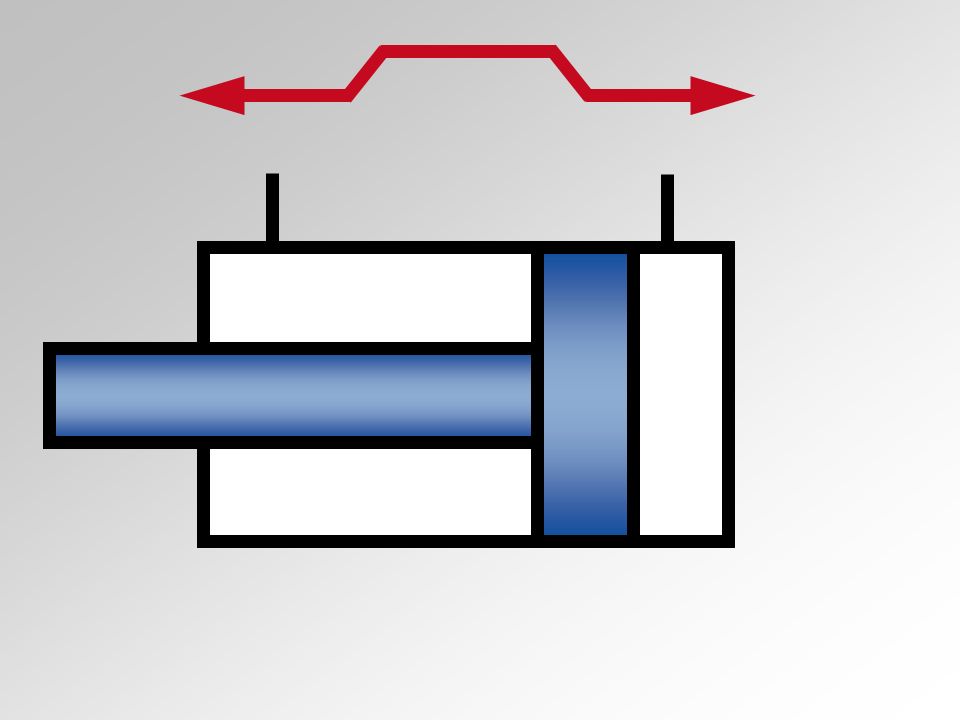

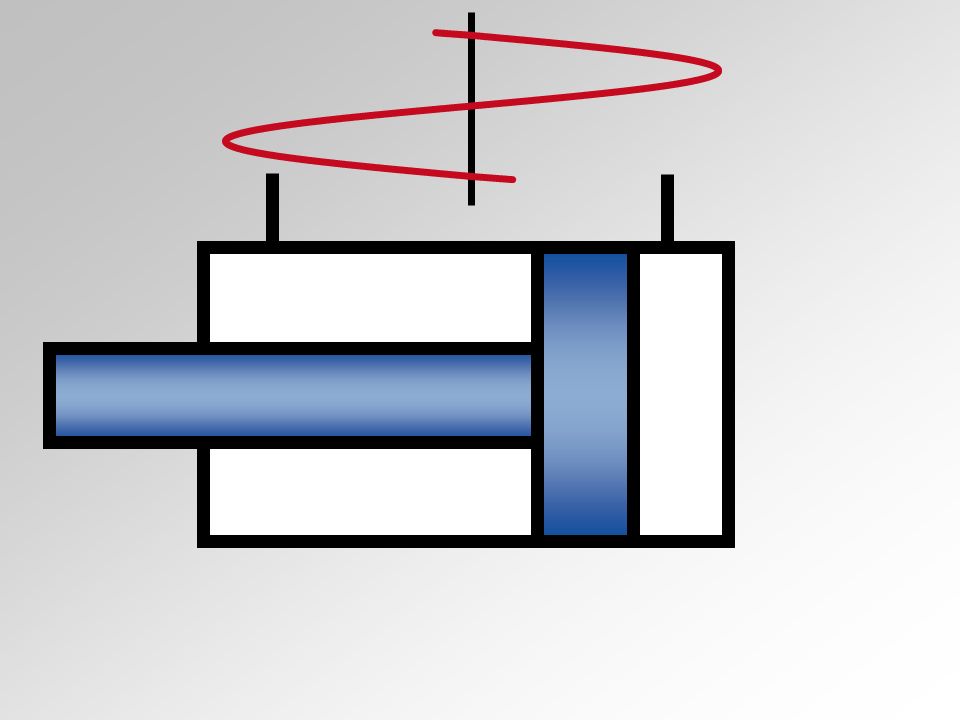

Controlled movement Controlled movement should be smooth. The sealing systems lip seal-wiper ring or Servocop® are recommended for such cases. |

|

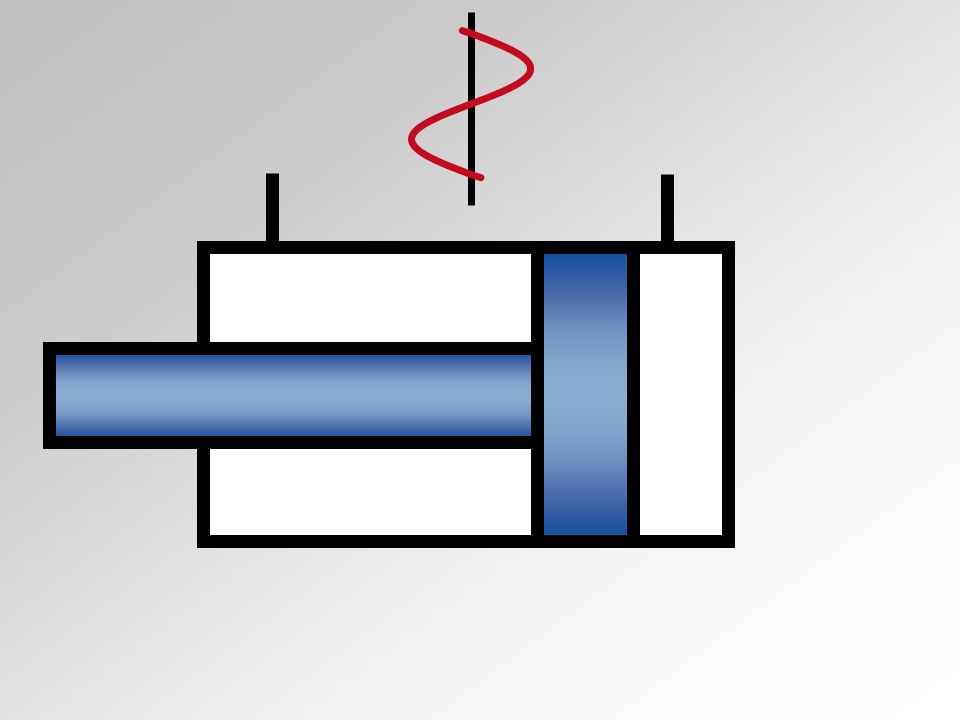

Sensitive movement Sensitive controlled movement requires that stick-slip be kept as low as possible. The sealing systems Servocop®, Servoseal or Servofloat® are recommended for such cases. |

|

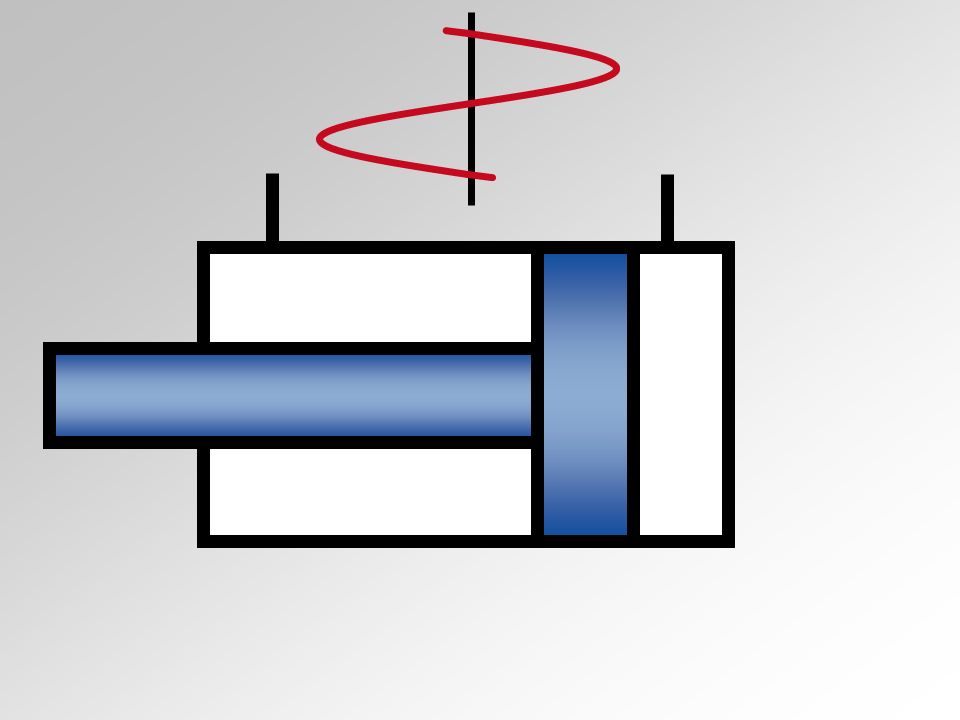

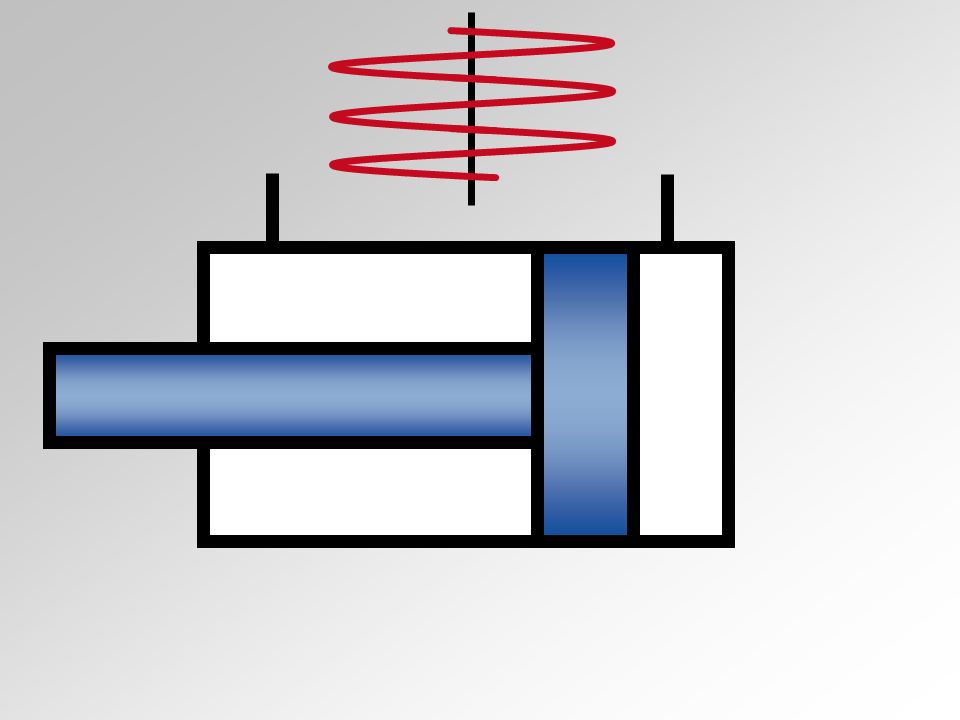

Short-stroke oscillation up to 25 Hz Applications with short-stroke oscillations are movements whose amplitude is smaller than the seal width. The sealing system Servoseal or Servofloat® is recommended for such cases. |

|

Long-stroke oscillation up to 25 Hz Applications with long-stroke oscillations are movements whose amplitude is larger than the seal width. The sealing systems Servocop®, Servoseal or Servofloat® are recommended for such cases. |

|

Highly dynamic movement > 25 Hz Highly dynamic movement requires inflexibility-optimized hydraulic cylinder designs. Especially cylinders of the 320 series are suitable for these applications. |

The proposal issues are based on nothing but the operating conditions requested here. Due to potential factors unknown to us, we cannot take any responsibility for the correctness of these recommendations.

In case of other influencing factors, please contact our application support.

www.haenchen.de | info@haenchen.de