Side loads

Proposal for the selection of hydraulic cylinder

The proposal for the selection of equipment features depend on a number of operating conditions.

The correct equipment is crucial for the hydraulic cylinder's quality and reliablity, its friction force and its wear behaviour.

Beside the operating temperatures and the travelling distances and speeds determined in the hydraulic design, especially the side loads applied to the cylinder's piston rod should be considered:

|

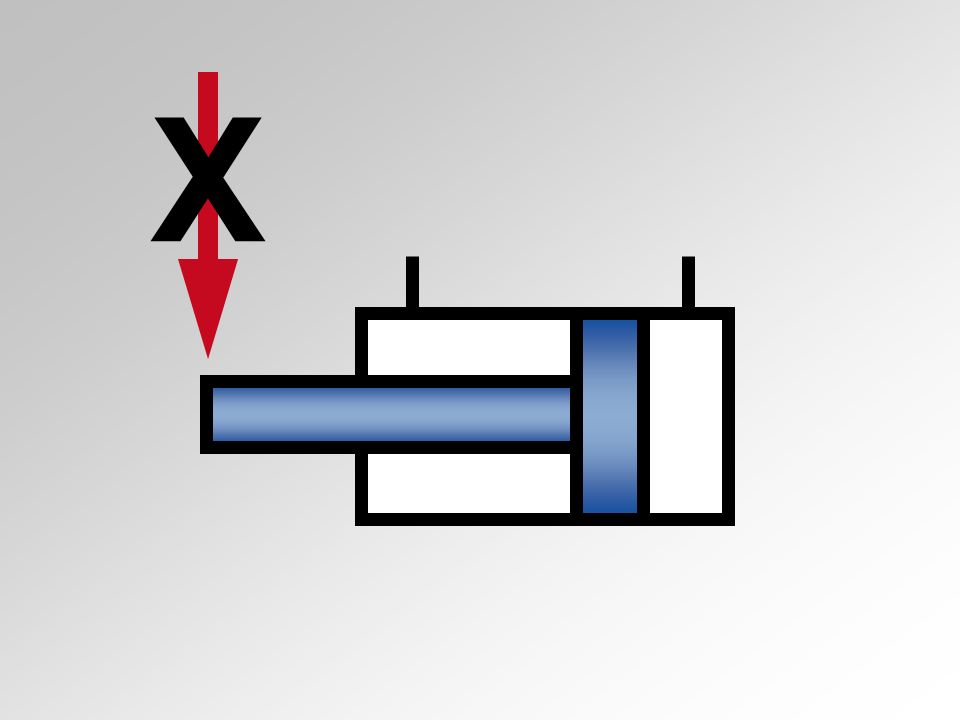

No side loads Ideally, a hydraulic cylinder is installed in such a way that the piston rod is not subject to any lateral forces. In such cases, a metallic guide system or the Servoslide® guide system on the cover is recommended. |

|

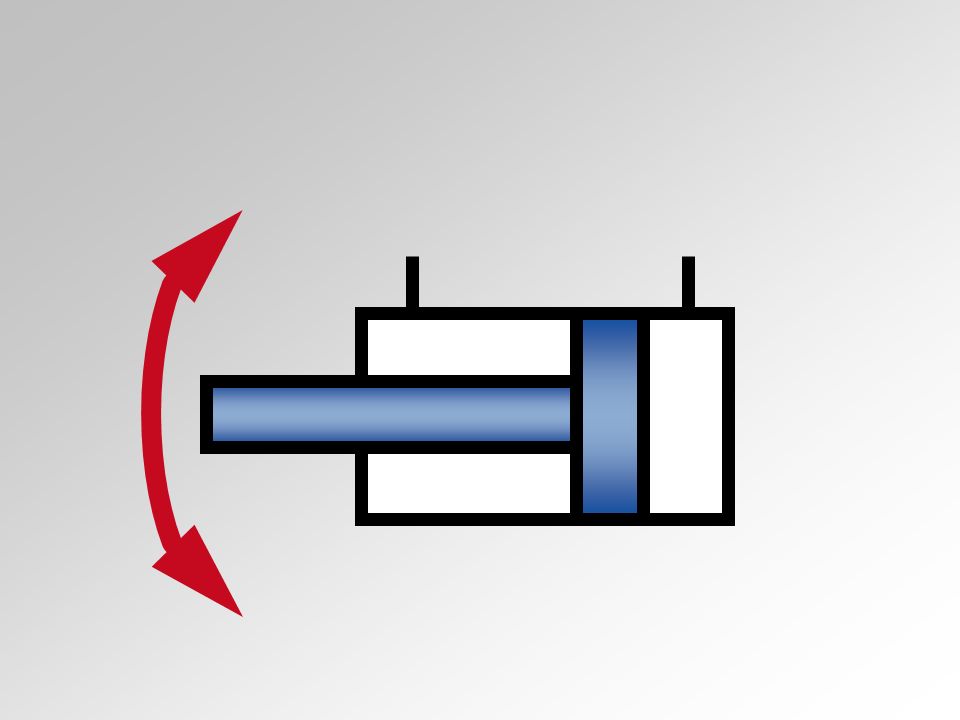

Side loads caused by transverse motion Pivot-mounted hydraulic cylinders, e.g. with spherical bearings, are often subject to lateral forces caused by transverse motions of the cylinder. Generally, hydraulic cylinders are designed for this; the guide system Servoslide® on the cover is recommended for such cases. |

|

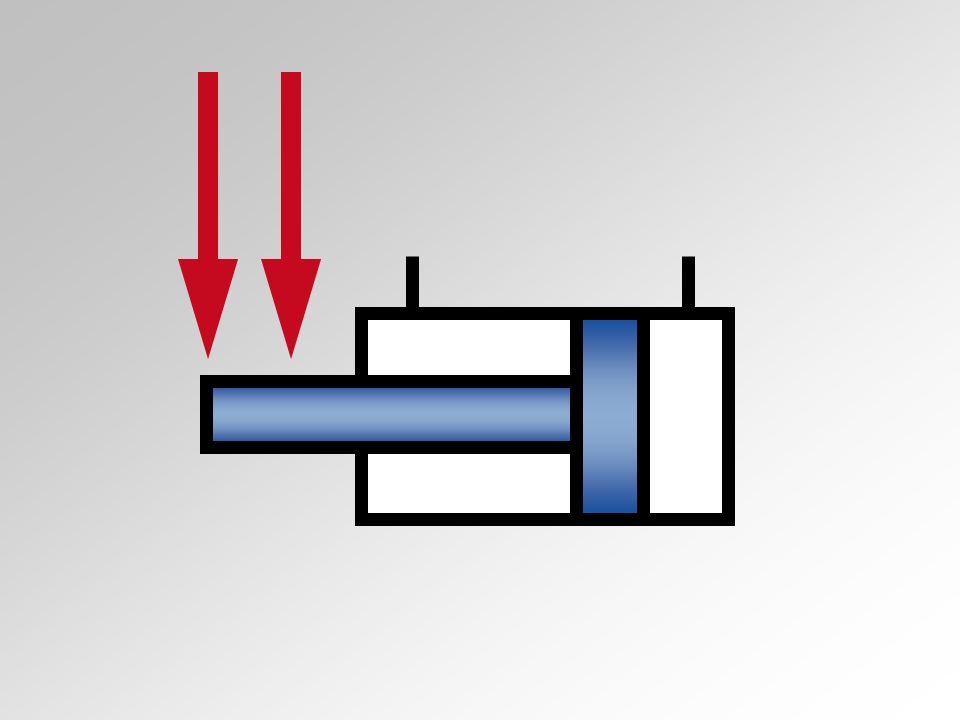

Very high side loads Highly dynamic movement can cause very high lateral forces on the piston rod of the hydraulic cylinder. Especially cylinders of the 320 series are suitable for such applications. |

The proposal issues are based on nothing but the operating conditions requested here. Due to potential factors unknown to us, we cannot take any responsibility for the correctness of these recommendations.

In case of other influencing factors, please contact our application support.

www.haenchen.de | info@haenchen.de