Control block

for set-up mode

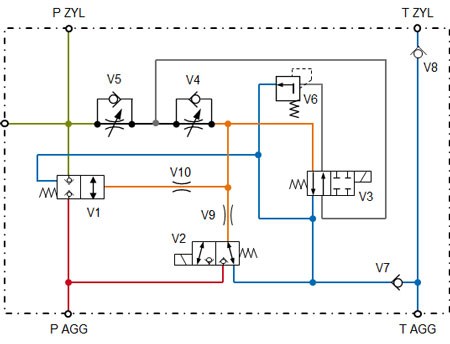

In hydraulic systems, functions for sequence and safety are realised with the help of electronic control systems in combination with hydraulic blocks. Such control blocks, in which the required valves are compactly housed, can be installed on or next to the cylinder, depending on the functionality.

Technical data control block

Our switch-on block, a standardised valve block

The Hänchen switch-on block is a standardised valve block with integrated functions:

- Adjustable low pressure for set-up operation in the range 10 to 100 bar

- Adjustable reduced flow for set-up operation in the range of approx. 2 to 25 l/min.

- Connection of high-pressure operation with defined pressure rise

| Type | Nominal flow [l/min] |

Port P | Port T |

| 1 | 65 | G3/4 | G3/4 |

| 2 | 130 | G1 | G1 |

| 3 | 250 | G1 ½ | G1 ½ |

The control block is made of galvanised steel and rated up to 280 bar.

The control block can be extended for further functions or designed in redundant form for applications with performance level up to PLe.

| Control block as switch-on block P AGG, T AGG: Connection on pump side (pressure supply) P ZYL, T ZYL: Connection cylinder side (consumer) |

Each control block is to be individually designed for the respective application. This customising is carried out by the hydraulic block specialists at Hänchen. Below you can find possible functions that may be integrated into the block.

Function: shut-off

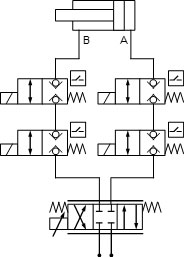

Shut-off block with shut-off function A-B

Directional valves, especially control valves, always leak due to their design. This is not relevant during operation, as the pressure supply provides sufficient volume flow. However, to prevent a cylinder from sinking under load in a pressureless state when installed vertically, lines A and B to the cylinder must be shut off separately.

Preferably, shut-off functions are integrated directly into valve plates and mounted directly onto the cylinder. This means that no hose connection is necessary between the valve block and the cylinder. Thus, the cylinder cannot sink even if the complete power supply fails or the hydraulic lines are damaged.

If leakages are to be expected in the hydraulic cylinder, e.g. due to functional oil of a floating gap seal, the functional oil lines must also be shut off separately accordingly.

In the case of hydraulic cylinders with throttle gap seals on the piston or hydrostatic bearings, this measure against sinking is not sufficient. Other precautions, such as a clamping unit, must be implemented here.

To prevent the piston rod, which is installed vertically downwards, from sinking, it is sufficient to shut off the rod side line. Shutting off both sides increases safety, however, as no pressure can then be applied on the piston side.

In combination with a safety control system, a performance level according to EN ISO 13849-1 up to PLe can be achieved by connecting two shut-off valves in series. In this case, the shut-off valves must be integrated into the control system with position monitoring according to EN ISO 13849-1 and the control system itself must meet the required safety standard.

| Control block with shut-off function A-B for PLe |

Function: switch-on mode

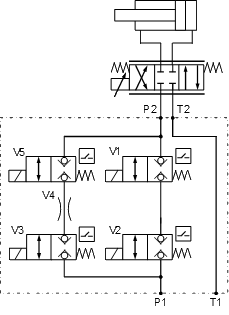

Safety block - shut-off function with reduced speed

Especially in switch-on mode, a machine must have the possibility to move each drive axis in reduced speed. Depending on the requirements and risk assessment, it may be necessary to perform this setup circuit as a safety function. For this purpose, a fixed throttle or a throttle that cannot be adjusted without tools and is also suitably secured shall be used in the control block.

In this circuit example of a control block, the flow required for the application with PLe in operation is separated by two shut-off valves V1 and V2.

Parallel to this, a bypass is set up with the shut-off valve V3 and the throttle V4, which provides a reduced flow for the switch-on operation.

Thus, the drive can be moved at a speed safely reduced by the throttle. Depending on the application and safety requirements, a further shut-off valve V5 may be necessary, which surrounds the throttle V4 with the shut-off valve V3.

| Control block with shut-off function A-B for PLe with reduced speed due to fixed throttle |