Test stand for seals and rod surfaces

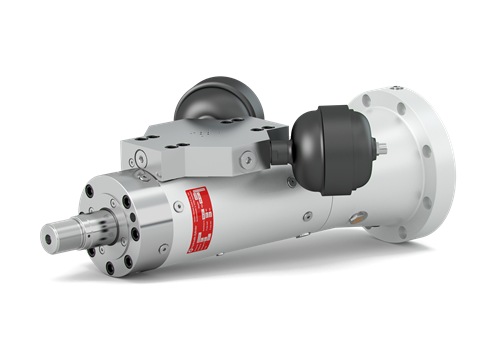

Servo hydraulic cylinder

In the sector of testing technology, Hänchen offers you individual components such as hydraulic test cylinders, hydrostatic bearing actuators, servo hydraulic cylinders and rod clamping units for your test field or your testing machine.

Here you will find examples of applications for test components such as hydraulic actuators, hydropulser servo actuators and rod clamping units, realised by Hänchen in the field of test bench technologys.

Servohydraulic lifecycle tests are also the current industry standard for automobile components that are used far beyond safety-related structural elements. The challenge for such testing facilities lies in bringing together widely varying technologies at the highest level.

Turbulence can cause the wing tips of the A 340-600 to move over four metres. The aeroplane is moved by 94 Hänchen hydraulic cylinders which form the core mechanical components of a time accelerator test, which simulates over a period of 18 months the sequences of movements of the entire life-span of an aeroplane lasting 25 - 30 years.

Hänchen offers one of the world's largest ranges of hydraulic cylinders for testing tasks. With our two series - servo hydraulic actuator series 300 and test hydraulic actuators, series 320 - and the various sealing and guiding concepts, we cover every application for testing tasks with hydraulic cylinders.